Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Murphy Thermal Energy Co., Ltd.

Brand: Murphy

Applicable Industry: Garment Shops, Food Shop, Building Material Shops, Printing Shops, Construction Works, Machinery Repair Shops, Energy &Amp; Mining, Manufacturing Plant, Food &Amp; Beverage Shops, Food &Amp; Beverage Factory, Restaurant, Home Use, Other, Farms

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Pakistan, Viet Nam, Philippines

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Pakistan, Philippines, Viet Nam

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Ordinary Product

Place Of Origin: China

Species: Fin Tube

Use: Heater Parts

Certification: Ce

Warranty Period: 1 Year

Service System: Free Spare Parts, Video Technical Support, Online Support

Packaging: wooden box

Productivity: 10000 Piece/Pieces per Month

Transportation: Ocean,Air,Express

Place of Origin: China

Supply Ability: TBD

Certificate: ISO90001

HS Code: 8108904090

Port: Shanghai

Payment Type: T/T

Incoterm: FOB,EXW

Extruded Fin Tube Properties:

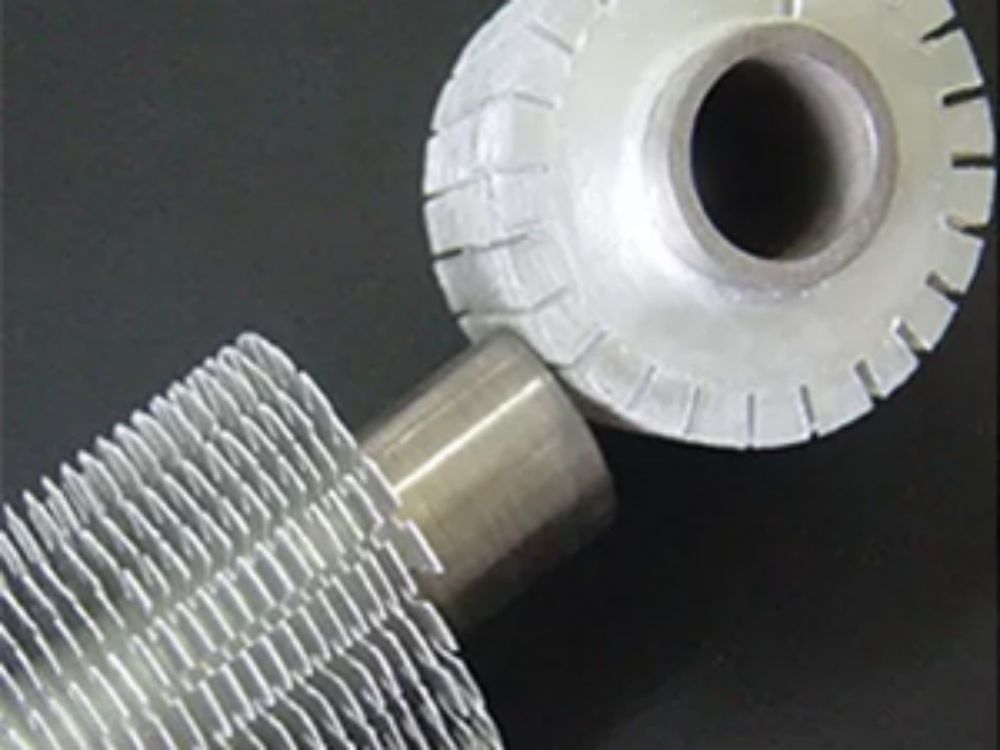

Cold Extrusion is the manufacturing process.

Excellent Fin-to-Tube Bond

Excellent Heat Transfer Efficiency

Mechanical Resistance: Excellent (as a result, unlike other fin tubes, it can be cleaned often with high-pressure jets). As a result, downtime is reduced and total life is increased.)

Corrosion Protection: Because it completely covers the base tube, it provides excellent corrosion protection (except bare ends).

Temperature Range: Up to 300 degrees Celsius

Extruded Finned Tube Manufacturing Process:

The fins are rotary cold rolled from a smooth thick walled hollow blank tube slid over the core tube. Three multi spindle disc packs extrude the hollow blank tube into helical high fins.

During this process the inner diameter of the hollow blank tube is reduced and at the same time pressed on the core tube. This results in a mechanically solid joint.

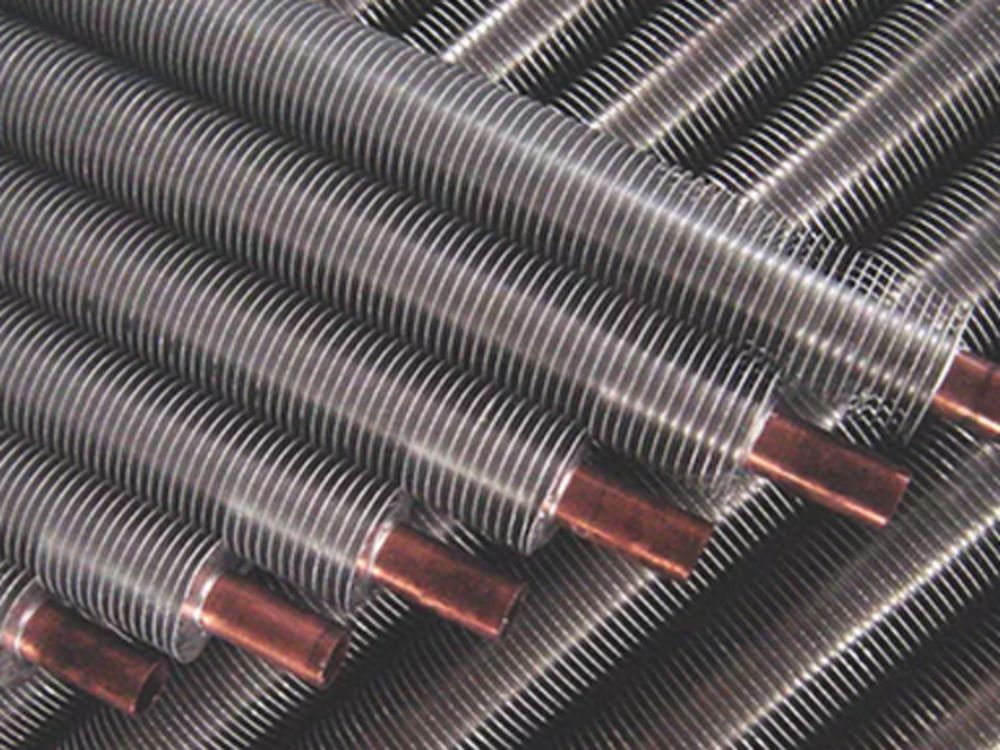

Fin Material: Aluminium/Copper.

Core Tube Material: Carbon Steel/ Carbon

Alloy Steel/Stainless Steel/ Nickel Alloys/Copper/Copper Alloys/Titanium.

Extruded Fin Tubes Advantages:

100% fin-to-tube bond providing exceptional efficiency and longevity.

Excellent corrosion protection on the base tube.

Easy to clean with a high-pressure water jet without deforming the fins.

As the outer sleeve is continuous No galvanic corrosion between the tube and fins.

The bonding of the outer and inner tubes removes the risk of loss of contact with the aluminium due to thermal stress and fins are vibration resistant.

Higher heat transfer performance for the life of the unit.

Extruded Finned tubes are commonly used in applications with temperature up to 325 °c.

Extruded Aluminum Tubing Product Description:

Extruded fin tubes "double-wall" construction makes them extremely durable and heat-efficient. In addition, our extruded fin tubes are designed to prevent corrosion between the fins and tube, unlike fins embedded in the exterior wall of the tube. Used properly, our tubes are entirely suitable for steam coils.

Extruded fin tubes are manufactured by a rotary extrusion process in order to obtain integral fin tubes. We manufacture them by inserting a lining in an aluminum extrusion. The extrusion is radially crushed on the lining, and the excess material is pushed into the shape of spiral fins. The extrusion process solidifies the fins and prevents the galvanic corrosion that would occur if there were two metal alloys exposed to air, as is the case with other types of fins. Compared to other similar products, our fins do not break, nor do they uncoil, and the lining does not come loose, thereby maintaining the Heat Exchanger's thermal performance.

Aluminum Extruded Tubing Applications:

Primary extruded finned tubes are used in high temperature conditions and corrosive atmospheric conditions, such as operating temperatures less than 300°C or off-shore applications,heat pipes air to air heat exchangers for HVAC applications,air dehumidification in air treatment plants, energy recovery in air exhaust system. This kind of fin design is the least economical as compared to the other fin types, main reason due to the increased amount of aluminum used around 40% also increased labors during the manufacturing. However this increased cost can be compensated if using lower grade parent tube material.

Extruded Aluminum Tube Specifications:

Product Specification Tube OD 10~51 (mm) 0.4”~2” Tube Wall Thk 1.65~3.0 (mm) 0.065”~0.118” Tube Length ≤18,500 (mm) ≤60.7 ft Fin Thk 0.3~1.2 (mm) 0.012”~0.047” Fin Height 5~16 (mm) 0.2”~0.63” Fin Pitch 100~555 (mm) 3~14 FPI Fin Type Extruded Material Combinations Fin Material Aluminum (most common grade:Alu.1100, Alu.1060, Alu. 6063) Copper Tube Material C.S. (most common grade: A179, A192,SA210 GrA1/C,A106 Gr B ) S.S. (most common grade: TP304, 316, 321, 347,A789) Copper (most common grade:UNS12200,14200, 70600, CuNi70/30, CuNi 90/10) Titanium (most common grade: B338Gr2) Applied

Temperature 300°C Type of Service Medium temperature, severe atmospheric corrosive environment.

Product Categories : Extruded Finned Tube

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.