Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Murphy Thermal Energy Co., Ltd.

Brand: Murphy

Status: New

Applicable Industry: Machinery Repair Shops, Manufacturing Plant, Energy &Amp; Mining, Other

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Ordinary Product

Place Of Origin: China

Species: Fin Tube

Use: Heater Parts

Certification: Ce

Warranty Period: 1 Year

Service System: Free Spare Parts, Video Technical Support, Online Support

Packaging: wooden box

Productivity: 10000 Piece/Pieces per Month

Transportation: Ocean,Air,Express

Place of Origin: China

Supply Ability: TBD

Certificate: ISO90001

HS Code: 8108904090

Port: Shanghai

Payment Type: T/T

Incoterm: FOB,EXW

Condenser Coils

A condenser coil is an essential component of any refrigerant system. Its primary functions are to remove heat from the refrigerant and support the conversion of the refrigerant back to a liquid state. Specifically, heat is removed as air passes over top of the coil while an integral or dedicated sub-cooling section directs the conversion of the refrigerant from a gas to a liquid. We’re condenser experts, with many years of experience designing and manufacturing them, typically using 5mm or 3/8” tubing.Our condensers are used in several industries, including gas compression, HVAC, military, transit cooling, refrigerated display cases, data center & electronics cooling, and ground support.

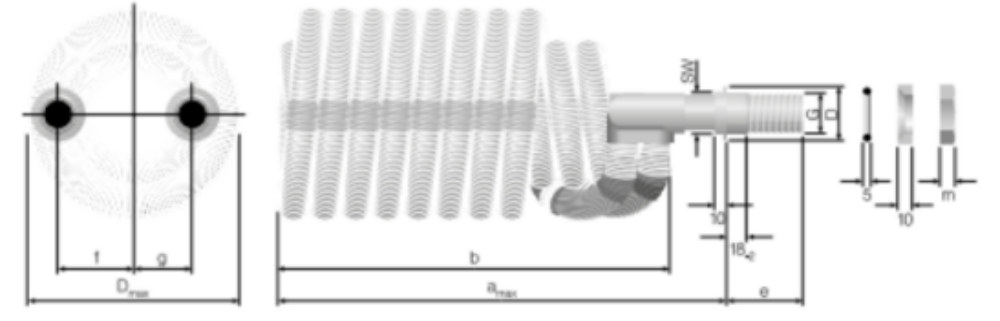

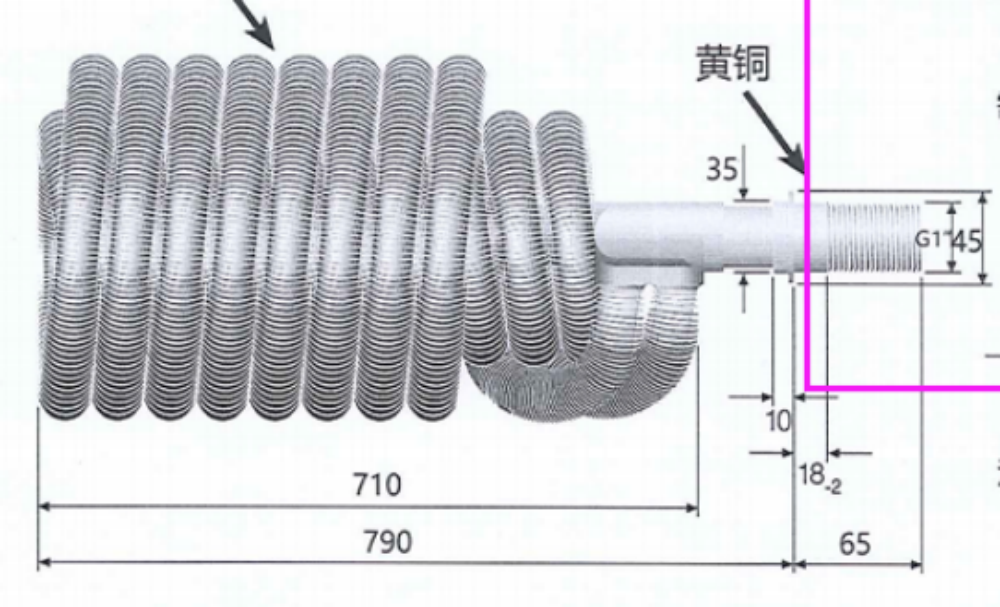

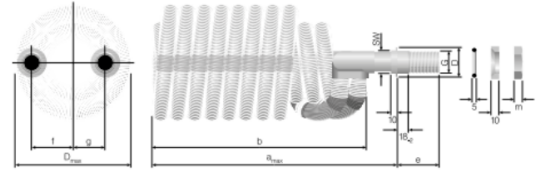

Fin Tube Coil Manufacturing Process:

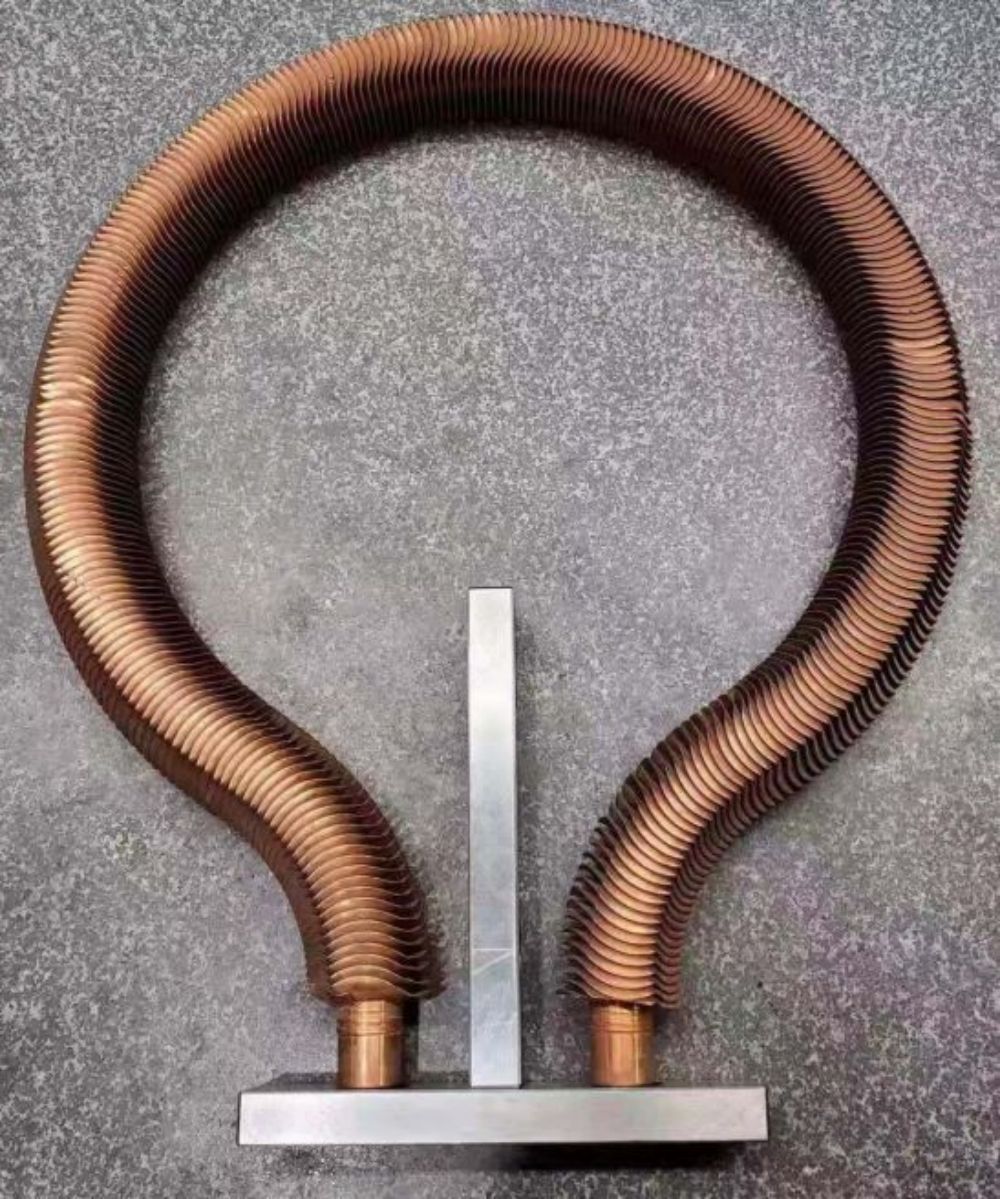

We can produce helical coils ranging from micro fin tube to large diameters according to customer’s requirement, including bare tubing, cone shaped and double wrap coil.We can handle any tube bending project.The finned tubing can be twisted and bent into numerous shapes. By forming a tube length into a U-shape, circle, square, or serpentine configuration, limited space is utilized rather than being wasted.

Finned Tube Coil Advantages:

• Advanced and reliable thermal selection capabilities

• Long life cycle / durability

• Corrosion resistance

• Energy saving

Fin Tube Coils(Coiled Steel Pipe) Properties:

Easy installation

High functionality

Corrosion resistance

Longer life/Durable

less clogging

low maintenance

Available with different material for different application.

Finned Tube Coils(Stainless Steel Coiled Pipe) Applications:

Our condensers are used in several industries, including gas compression, HVAC, military, transit cooling, refrigerated display cases, data center & electronics cooling, and ground support.

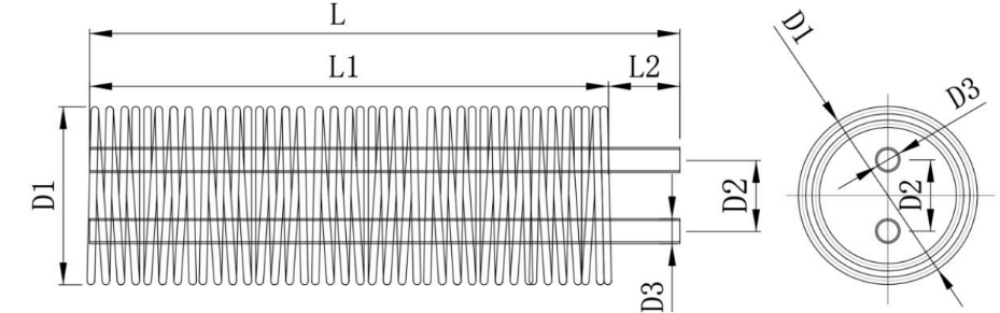

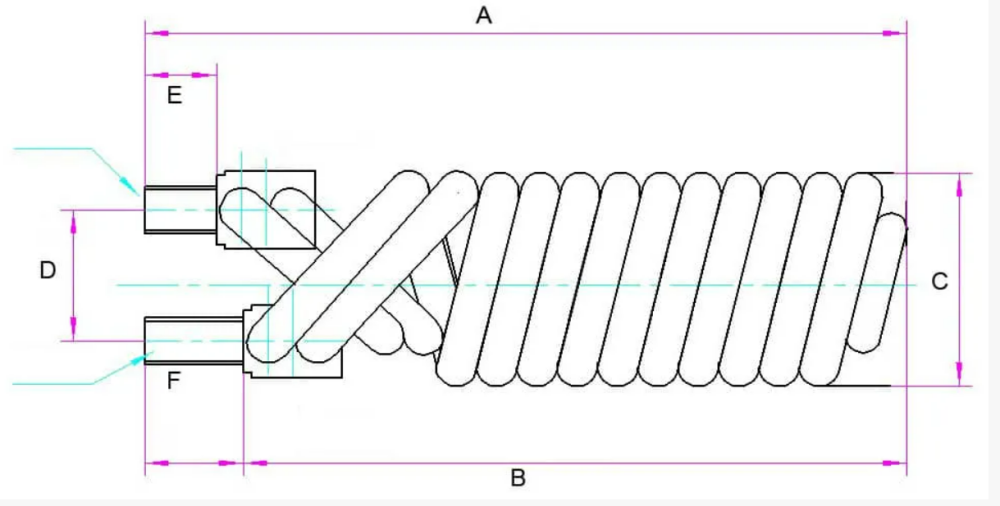

Fin Tube Coil Specifications:

| Product Specification | ||

| Tube OD | 12~25 (mm) | 0.47"~1.0" |

| Tube Wall Thk | 1~5 (mm) | 0.04"~0.20" |

| Tube Length | ≤28,000 (mm) | ≤92 ft |

| Fin Thk | 0.5~2.5 (mm) | 0.02"~0.10" |

| Fin Height | 6~13 (mm) | 0.24"~0.51" |

| Fin Pitch | 1.8~4 (mm) | 6~14 FPI |

| Fin Type | Solid,Serrated,Extruded | |

| Material Combinations | ||

| Fin Material | C.S. (most common grade:A179,A192,A210, Gr.A1/C, A106 Gr.B) | |

| S.S. (most common grade:TP304,TP316,TP321,TP347,A789) | ||

| Aluminum | ||

| Cu(most common grade:TP2) | ||

| Tube Material | C.S. (most common grade: A106 Gr.B) | |

| S.S. (most common grade are TP304,316, 321, 347) | ||

| Cu (most common grade:C12200,C14200, C70600,CuNi 70/30,CuNi 90/10) | ||

Product Categories : Fin Tube Coil

Finned tube coil

Fin Type: fin tube coil

Tube: copper, steel or stainless steel

Fins: aluminium, copper, steel or stainless steel

Fin Tube Length: No Limit

Product description:Finned tube coil are available in many products like air heaters, air coolers, condensers, heat exchangers and evaporators for HVAC and various other industrial applications.

Finned tube coils are commonly used for gas-liquid exchange. Heat transfer on the gas side is usually much lower than on the liquid side, and heat sinks are required on the gas side. The outer fins of the tube may be normal on a single tube, or maybe transverse, spiral, or longitudinal. Longitudinal fins are commonly used in a double tube or shell heat exchangers without baffles. A fluid may be a gas or a viscous liquid. Our finned tube coil products range from small applications to large commercial and industrial projects.

Tube: copper, steel or stainless steel

Fins: aluminum, copper, steel or stainless steel

Spiral wound – crimped fin wound along tube length

Water to air

Steam to air

Refrigerant to air

Oil to air

Run-around coils (air to air heat recovery)

Industrial Coils: heat exchangers, boilers, petroleum, chemical, fertilizer, chemical fiber, nuclear power, etc. Coils for fluids: beverages, beer, milk, water supply systems, equipment, etc. Coil for mechanical structures: printing and dyeing, printing, textile machinery, appliances, kitchen equipment, automobile and ship accessories, construction and decoration, etc.

For example: The fin tube coil is widely used in the distillation condenser and solvent cooler of the washing machine, and is an ideal accessory product; the tube and the fin of the finned tube are an integrated structure, and the heat transfer capacity is increased by 30% compared with the smooth tube -40%, widely used in the washing industry; the surface can be treated with electrophoresis, electroless nickel plating, tin plating and other anti-corrosion processes, which can greatly improve the corrosion resistance.

Frequently Asked Questions (FAQ) About Fin Tube Coil:

1. What are fin tube coils?

What do they do? Finned tube coils transfer heat energy from a steam or liquid (inside the tubes) into air (across the fins) or vice versa. We produce finned tube coils from one off small applications to much larger commercial and industrial projects. The list of applications are endless!

2. What is the purpose of the fins on finned tube coils?

The fins on a coil accomplish two major functions: they straighten the air out as it comes in contact with the entering-air side of the coil, and they perform some of the heat transfer. Understand the basics of finned tube coils and maximize coil capacity and efficiency.

3. What is the primary heat transfer surface in a fin tube coil?

In a fin-tube coil, the tubes are the primary heat transfer surface and the fins are the secondary heat transfer surface. It is important to have good metal contact between the fins and the tubes because without it, there is not a thermal pathway for heat to move. Temperature Difference Between the Two Mediums.

4. Why HVAC coils use copper tubes and aluminum fins?

Copper is great for heat transfer, and aluminum – while still very effective -is simply not as good. The first goal of any HVAC coil is to cool or heat. Heat transfer is always the first consideration. Cost is the second. Copper works well for the tubes, but would be prohibitive for the fins. You would need a compelling reason for the fins to be copper, and sometimes there are reasons to do just that. However, the vast majority of HVAC coils that you see are built with copper tubes and aluminum fins. That combination offers the most effective heat transfer at the most efficient cost. To begin, fins are responsible for a surprising 65% – 70% of the heat transfer on any coil, while tubes are responsible for the remaining 30% – 35%. Additionally, in order for your coil to work at optimum performance, you need to have a terrific fin/tube bond. Fins are known as secondary surface, while tubes are referred to as primary surface. While this may seem counterintuitive, the secondary surface is responsible for twice the amount of heat transfer as the primary surface.

The tubes are expanded into the fins, and for that reason, the fins become secondary. As mentioned above, the fins are responsible for 65% – 70% of all heat transfer that takes place in the HVAC coil. When you think about it logically, it really makes sense. At 8 fins/inch or 10 fins/inch, and with fins that run the height and depth of the coil, there is much more fin surface than tube surface. However, it also points out how good the fin/tube bond must be in the expansion process. Without that bond, the fins cannot perform their job.

Understanding the role and importance of the materials used in HVAC coils cannot be overstated. There is a distinct reason why the vast majority of coils are constructed using these materials. While coils can be built with other tube materials, such as steel, 304/316 stainless steel, 90/10 cupro-nickel, as well as various different fin materials, none of these are as efficient or economical as copper/aluminum.

5. What about cleaning the coil?

Understanding some basic principles will help ensure that when you clean your coils, it is done correctly. The most important part of cleaning a coil is knowing the type of product used and at what pressure. You must understand that some coils have very thin fin surfaces, and high pressure cleaning may clean the coil but close off the fin surface by bending the outer edges.Also, once the coil is cleaned, make sure that the cleaning agent is removed completely. I have seen hundreds of coils destroyed by corrosion caused by cleaning agents.

Clean your coils on a regular basis, and never let airborne particles find their way into the internal rows of any coil. You have a chance to clean a multi-row coil if the material is still on the outside area of a coil, but you won’t have much success if the material has moved more than two rows into the center of the coil.

And remember, prevention is worth its weight in gold. Why deal with fouled, inefficient coils when you can remove these foreign agents before they ever arrive at the surfaces? High quality filtration may seem like a huge expense, but it is pennies on the dollar in comparison to the costs of downstream contamination.

6. How do you ensure a quality product?

We adhere to an in-house Quality System (or QMS) based on Industry Standards such as ASME, the National Board of Boilers & Pressure Vessels, and customer requirements.Our quality system is documented, audited, and enforced by our Quality Control department.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.