Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Murphy Thermal Energy Co., Ltd.

Brand: Murphy

Applicable Industry: Hotels, Farms, Garment Shops, Restaurant, Building Material Shops, Home Use, Machinery Repair Shops, Retail, Printing Shops, Manufacturing Plant, Construction Works, Energy &Amp; Mining

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Germany, Viet Nam, Philippines, Pakistan

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Ordinary Product

Place Of Origin: China

Species: Heat Exchanger Tube

Use: Heater Parts

Certification: Ce

Warranty Period: 1 Year

Service System: Free Spare Parts, Video Technical Support, Online Support

Packaging: wooden case

Productivity: 10000 Pieces

Transportation: Ocean,Land,Air,Express

Place of Origin: China

Supply Ability: 10000 pieces

Certificate: ISO89001

HS Code: 84199090000

Port: Shanghai

Payment Type: T/T,D/P,Money Gram,Western Union,Paypal

Incoterm: FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP,DDP,DDU

Extruded Fin Tube Product Description:

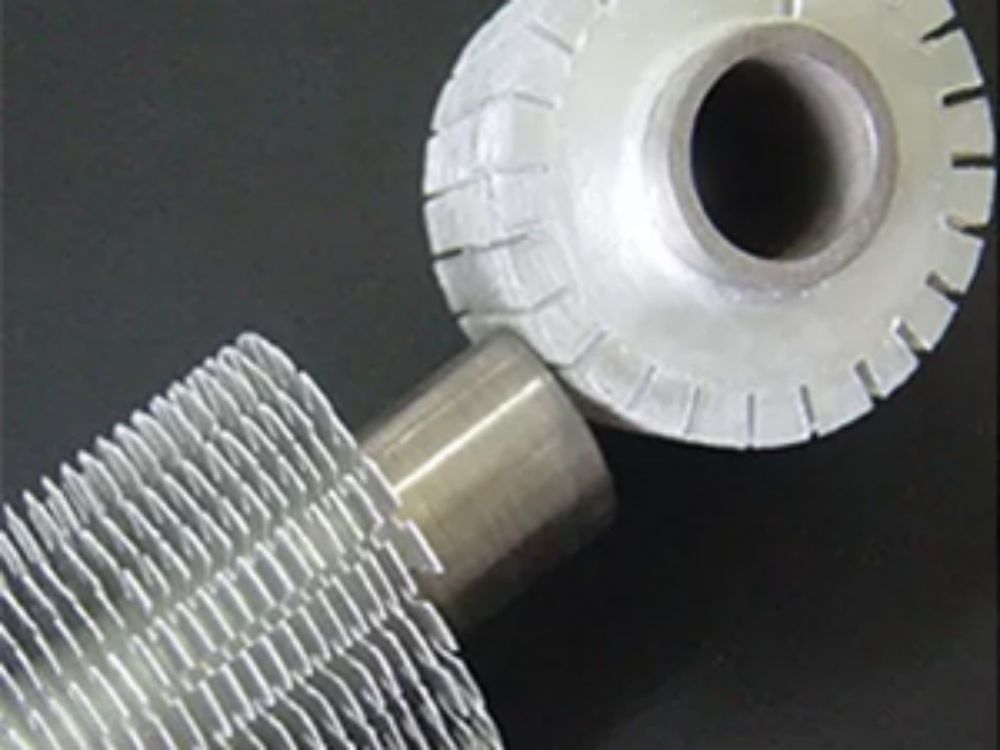

Extruded Fin Tube, also known as Bimetallic Fin Tube, is a popular finning method for a variety of applications. The fins are created by extruding them onto an aluminium muff tube that is built to fit over the base tube with a tight tolerance.

Extrusion is performed using a Continuous Fin Extruder with Three Tooling Rolls, and high pressures in the range of 1200 psi are used. The cold working procedure ensures a perfect bond between the tube and the fin, resulting in great heat transfer efficiency. Simultaneously, the mechanical strength of the fins is greatly improved.

Fin Tubes are used in AIR FIN COOLERS, DRIERS, RADIATORS, and other applications in industries such as food and agriculture, power plants, chemical industries, steel plants, and chiller plants, among others.

Extruded Finned Tube Manufacturing Process:

A polished and deoiled base tube is set in an aluminium sleeve. The whole goes through the fin-machine which consists of three spindles set at 120° each on bearing a stack of plates. These plates, stacked in from and diameter first build the fin, then bond the outer and inner tubes together. In certain cases (high air speed) the fins are serrated after fin process so as to increase the heat transfer coefficient.

Extruded Fin Tubes Advantages:

Relative thin wall core tubes can be used.

Excellent heat transfer performance (100% contact between tube and fin).

Excellent atmospheric corrosion (complete coverage of the core tube).

Airtight fin to tube bond.

Robust fins resist mechanical damage.

Can be cleaned with high pressure water/steam.

Fin Contact: Interference fit with mechanically solid pressed bond.

Maximum Tube Wall Operating Temperature:

300°C.

Type of Service: Medium temperature, severe atmospheric corrosive environment.

Extruded Aluminum Tubing Properties:

Aluminum fins are formed from a bimetallic tube consisting of a base tube and an aluminium muff tube. The fins are formed on a cold rolling process from the wall thickness of the aluminium muff tube. Extruded fin gives very good corrosion protection to the base tube, as the base tube is not visible to the atmosphere inbetween the fins.

Maximum operating temperature for extruded finned tube is 325 deg C.

Fin Material - Aluminium (or) Copper

Tube Material - No theoretical limit

Aluminum Extruded Tubing Applications:

These Fin Tubes find application in AIR FIN COOLERS, DRIERS, RADIATORS etc and are preferred in Industries like Food and Agriculture, Power Plants, Chemical Industries, Steel Plants, Chiller Plants etc.

Extruded Aluminum Tube Specifications:

| Product Specification | ||

| Tube OD | 10~51 (mm) | 0.4”~2” |

| Tube Wall Thk | 1.65~3.0 (mm) | 0.065”~0.118” |

| Tube Length | ≤18,500 (mm) | ≤60.7 ft |

| Fin Thk | 0.3~1.2 (mm) | 0.012”~0.047” |

| Fin Height | 5~16 (mm) | 0.2”~0.63” |

| Fin Pitch | 100~555 (mm) | 3~14 FPI |

| Fin Type | Extruded | |

| Material Combinations | ||

| Fin Material | Aluminum (most common grade:Alu.1100, Alu.1060, Alu. 6063) | |

| Copper | ||

| Tube Material | C.S. (most common grade: A179, A192,SA210 GrA1/C,A106 Gr B ) | |

| S.S. (most common grade: TP304, 316, 321, 347,A789) | ||

| Copper (most common grade:UNS12200,14200, 70600, CuNi70/30, CuNi 90/10) | ||

| Titanium (most common grade: B338Gr2) | ||

| Applied Temperature | 300°C | |

| Type of Service | Medium temperature, severe atmospheric corrosive environment. | |

Product Categories : Extruded Finned Tube

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.