Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Murphy Thermal Energy Co., Ltd.

Brand: Murphy

Applicable Industry: Construction Works, Manufacturing Plant, Machinery Repair Shops, Energy &Amp; Mining, Farms, Restaurant, Hotels, Building Material Shops, Retail, Home Use

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Viet Nam, Germany, Philippines, Pakistan

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Ordinary Product

Place Of Origin: China

Species: Fin Tube

Use: Heater Parts

Certification: Ce

Warranty Period: 1 Year

Service System: Free Spare Parts, Video Technical Support, Online Support

Packaging: wooden case

Productivity: 1000 pieces

Transportation: Ocean,Land,Air,Express

Place of Origin: China

Supply Ability: 1000 piece

Certificate: ISO9001

HS Code: 940290000

Port: Shanghai

Payment Type: L/C,T/T,D/P,D/A,Paypal

Incoterm: FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP,DDP,DDU,Express Delivery

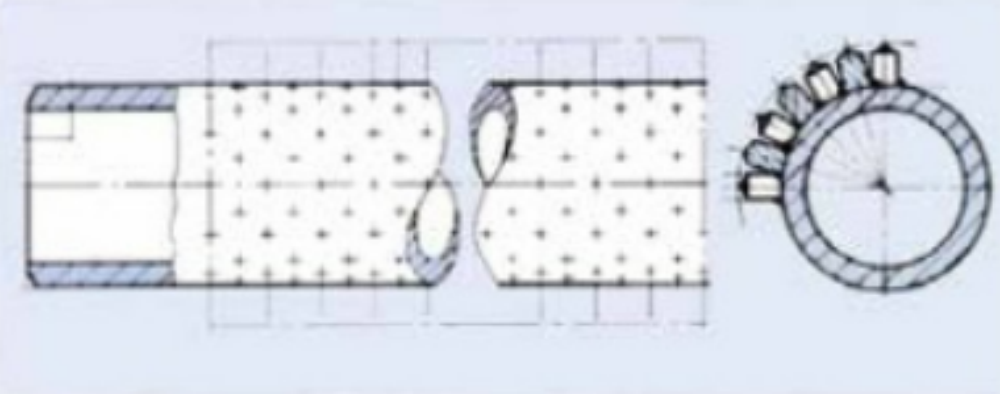

Studded Tube Product Description: The stud pipe or stud tube is used by refining and petrochemical industries for many different applications - including fired heaters and furnaces. It’s also used as an alternative to high frequency welded finned tubes (HF finned tubes). Studs are attached to the pipe around the circumference in completely opposing pairs by means of electrical resistance welding. They are attached to ensure a high integrity bond for strength and heat flow. A bonus of studded pipe is that it’s relatively easy to clean. It’s ideal for applications where heavy fouling of the external surface may occur, or for processes undertaken in harsh environments, where dirty fuels are used. The surface can be efficiently shot blasted (without damaging it). Studded Tube(Stainless Steel Welded Tube) Manufacturing Process: The steel studs are automatically resistance welded to the tube, producing high quality forge welds. The welding process enables the combination of any grades for studs and tube: carbon, low alloy, stainless steels and high nickel alloys. Studded Tube(Welded Stainless Tube) Advantages: To increase the surface area of the tube and to protect tube surface from direct exposure to heat /corrosive environment. Studding reduces the amount of bare pipes used in these processes. Heat transfer surface of one studded pipe is equivalent to surface of 4 to 10 bare pipes. Use of studded tubes is ideal for processes/applications, where dirty fuels are used in harsh environments. Studded Tube(Black Welded Pipe) Properties: Manufacturing Process:- Electric Resistance Welding Fin To Tube Bond:- Excellent Heat Transfer Efficiency:- Excellent Mechanical Resistance:- Excellent (Hence can be frequently cleaned with high pressure jets unlike other fin tubes. Thereby reducing down time and increasing overall life) Corrosion Protection:- Gives excellent corrosion protection to the base tube since it entirely covers the base tube (except bare ends). Temperature Range:- Depending on Properties of material of Fin (Stud) and Pipe Studded Tube(Weld Galvanized Pipe) Applications: High density crude oil is passed through studded tubes which are heated from outside. Liquefied product comes out from the other end, which now can be used for further processing. At times, navy boilers also require studded tubes, with oval shaped studs welded on them. These are used for heating water in water tube boilers. Studded Tube(Fin Tube) Specifications:

Product Specification Tube OD 25~273 (mm) 1”~10” (NPS) Tube Wall Thk 3.5~28.6 (mm) 0.14”~1.1” Tube Length ≤25,000 (mm) ≤82 ft Stud Thk 6~25.4 (mm) 0.23”~1” Stud Height 10~35 (mm) 0.4”~1.38” Stud Pitch 8~30 (mm) 0.3”~1.2” Stud Type Cylindrical, Elliptical, Lens type Stud to tube surface angle Vertical or Angular Material Combinations Stud Material C.S. (most common grade: Q235B) S.S. (most common grade are AISI 304, 316, 409, 410, 321,347) A.S. Tube Material C.S. (most common grade: A106 Gr.B) S.S. (most common grade are TP304,316, 321, 347) A.S. (most common grade are T/P5,9,11,22,91) Type of Service High temperature

Product Categories : Studded Tube

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.