Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Murphy Thermal Energy Co., Ltd.

Brand: Murphy

Status: New

Applicable Industry: Machinery Repair Shops, Manufacturing Plant, Energy &Amp; Mining, Other

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Ordinary Product

Place Of Origin: China

Species: Fin Tube

Use: Heater Parts

Certification: Ce

Warranty Period: 1 Year

Service System: Free Spare Parts, Video Technical Support, Online Support

Packaging: wooden box

Productivity: 10000 Piece/Pieces per Month

Transportation: Ocean,Air,Express

Place of Origin: China

Supply Ability: TBD

Certificate: ISO90001

HS Code: 8108904090

Port: Shanghai

Payment Type: T/T

Incoterm: FOB,EXW

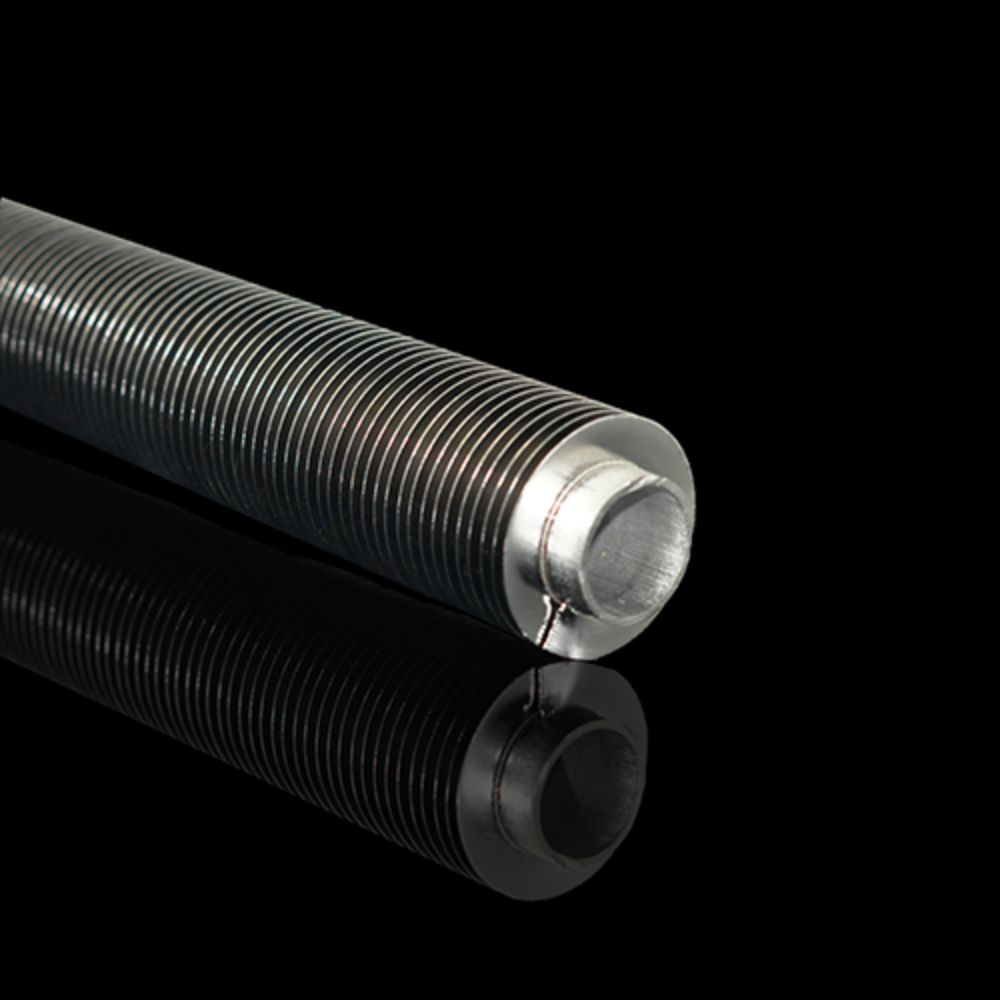

Laser Welded Finned Tube Product Description:

The complete connection between the fins and the base tube brings about excellent heat transfer and up to 2.5 times higher thermal performance of the Fin Tube.

The continuous weld prevents notch effects and corrosion and the formation of cracks are hence avoided also in the case of possibly oscillating finned tubes.

The low base metal heating during welding and the high speed of travel of up to 20m/min. minimize the heat-affected zone in the base tube. Complete melting of the tube and a related metallurgical transformation of the parent metals are hence excluded.

Laser Welding Fin Tube Manufacturing Process:

The fin strip is welded continuously and spirally wound onto a polished bare tube. And the tube and fins are bonded together by using advanced laser welding technique.

Laser Welding Fin Tube(Welded Spiral Pipe) Advantages:

Laser welded finned tubes are manufactured and comply with the highest requirements

Does not require the use of welding wire

Elimination of shielding gases in the welding process

Improved manufacturing efficiencies

The manufacturing process is designed to operate in continuous production mode which translates into no interruptions in the technological process as required.

All lead to significant reduction of manufacturing costs

Laser Welded Finned Tube(Stainless Steel Welded Pipes) Properties:

100% welding between fin and base tube without using any filler material.

The laser welding process is carried out under the protective atmosphere, and no impurity of the weld seam.

Laser Welded Finned Tube(Stainless Steel Welded Pipe) Applications:

The fin tubes are mainly used in heating (gas-fired boilers, condensing boilers, flue gas condensers), in mechanical and automotive engineering (oil coolers, mine coolers, air coolers for diesel engines), in chemical engineering (gas coolers and heater, process cooler), in power plants (air cooler, cooling tower), and in nuclear engineering (uranium enrichment plants).

Laser Welded Finned Tube(Spiral Welding Pipe) Specifications:

Product Specification Tube OD 10~215 (mm) 0.4”~8.5” Tube Wall Thk 1~6 (mm) 0.04”~0.24” Tube Length ≤18,500 (mm) ≤60.7ft Fin Thk 0.3~2.0 (mm) 0.01”~0.08” Fin Height 3~30 (mm) 0.12”~1.2” Fin Pitch 2~20 (mm) 1~13 FPI Fin Type Solid, Serrated Material Combinations Fin Material S.S. C.S. Aluminum Copper Titanium Tube Material S.S. C.S. Copper Titanium Applied

Temperature 450°C Type of Service High temperature

Product Categories : Laser Welded Finned Tube

Fin Type: Laser welded finned tube

Tube Material: steel, copper, titanium etc.

Fin Material: steel, aluminum, copper, titanium etc.

Product description:100% welding between fin and tube without using filler material. No impurity of the weld seam, as the laser welding is carried out under a protective atmosphere.

Laser welding finned tube is processed by laser welding machine. Laser welding is a welding method that irradiates a high-intensity laser beam onto the metal surface. Through the interaction of the laser and the metal, the metal absorbs the laser light and converts it into heat, melting the metal to form a cooling crystal. Laser welding machine is the most advanced laser welding equipment for finned tubes. Because the welding process is fully automatic and mechanical, the scientific and technological content and quality of laser welding finned tubes are superior to traditional cooling tubes.

The laser welding finned tube has a fully automatic welding process, saving manpower costs; secondly, the laser welding fin is firm, strong, and the test with high tensile strength is qualified. Laser welding is more efficient.

1. The laser welding finned tube (finned tube) fin machine has a high degree of automation, and the welding of the fin to the tube and the winding of the tube are synchronized

2. 100% welding rate, laser welding finned tube and fins are strong, the welding strength exceeds 600MPa.

3. The precision of laser welding tube finishing machine is up to 0.05mm

4. 0 contact resistance, achieve high efficiency of heat transfer of spiral finned tube by laser welding.

5. Save production costs. The laser welding finned tube (finned tube) has a smaller fin spacing, less than 2.5mm. Compared with the high frequency welded spiral (spiral) finned tube, the heat transfer area is increased by about 50%, which makes the material cost Reduced, volume reduced heat exchanger.

6. The advantages over conventional MAG / HF welding are of decisive importance. The complete connection between the fin and the base tube brings excellent heat transfer, and the thermal performance of the fin tube is increased by 2.5 times. Continuous welding prevents the notch effect, thereby avoiding the formation of v-corrosion and cracks under the condition that the finned tube may swing. The heating of base metals during welding is low and the travel speed is up to 20m / min. Minimize the heat affected zone in the base tube. Therefore, it does not include the complete melting of the tube and the related metallurgical transformation of the parent metal.

· Tube outside diameter 8.0–50.0 mm

· Fin outside diameter 17.0 –80.0 mm

· Fin pitch 5 –13 fin/inch

· Fin height 5.0 –17 mm

· Fin thickness 0.4 – 1.0 mm

· Maximum tube lengths 12.0 m

Frequently Asked Questions (FAQ) About Laser Welded Finned Tubes:

1. What are finned tubes used for?

Finned tubes are the main components of heat exchangers. They are a series of tubes where fins have been added on the outside to increase the contact area with the outside fluid, to exchange heat and between the fluid inside the tube and the fluid outside the tube.

2. How are finned tubes made?

The finned fin tube is simple to manufacture. The metal band is mechanically or welded around one end of the tube. The metal band is tightly wound on the outer wall of the tube by the torque of the tube. The other end is fixed to form a finned fin tube.

3. What are features of Laser Welded Finned Tubes?

· thin, continuous weld seam

· small heat-affected zone

· only slight discoloration weld site

· only slight microstructural change in tube and fin

· high utilization of heat for forming the seam

· increased safety because of the avoidance of crevice corrosion due to the high weld integrity between tube and fin

· no impurity of the weld seam, as the Laser-welding is carried out under a protective atmosphere

4. What is fin welding?

In the fin tube welding process rolled steel strip is continuously welded in spiral form on the outside diameter of a tube. The weld produced in this process is a true forge, blacksmith weld. This type of weld is comprised of a fusion between two portions of parent metal without the introduction of a filler material.

5. Where are Laser Welded Finned Tubes used?

The Laser Welding Finned Tubes find the preference in the following industrial sectors:

· Food processing;

· Chemical engineering;

· Energy & Power;

· Medicine and pharmacy;

· Rail power;

· Electromechanical device;

· Military industries;

· Domestic gas heaters.

6. How do you ensure a quality product?

We adhere to an in-house Quality System (or QMS) based on Industry Standards such as ASME, the National Board of Boilers & Pressure Vessels, and customer requirements. Our quality system is documented, audited, and enforced by our Quality Control department.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.