Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Murphy Thermal Energy Co., Ltd.

Brand: Murphy

Status: Used

Applicable Industry: Machinery Repair Shops, Manufacturing Plant, Food &Amp; Beverage Factory, Retail, Printing Shops, Construction Works, Energy &Amp; Mining, Food &Amp; Beverage Shops

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Viet Nam, Philippines, Pakistan

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Viet Nam, Philippines, Pakistan

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Ordinary Product

Place Of Origin: China

Species: Heat Exchanger Tube

Use: Heater Parts

Certification: Ce

Warranty Period: 1 Year

Service System: Free Spare Parts, Video Technical Support, Online Support

Packaging: Wooden Box

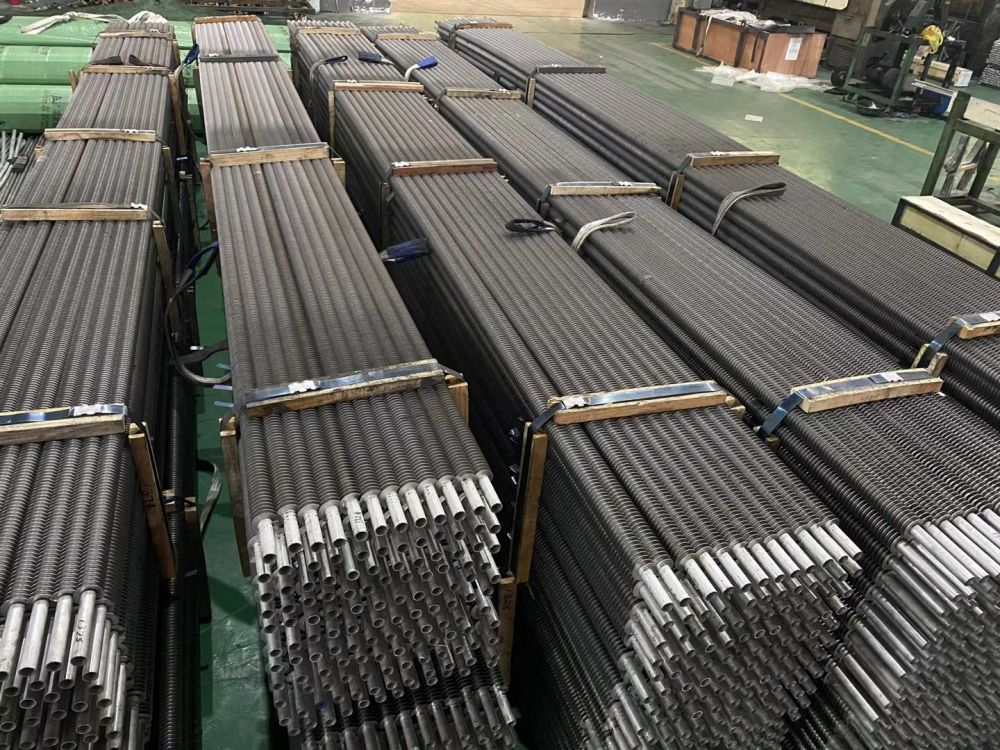

Productivity: 10000 Pieces Monthly

Transportation: Ocean,Land,Air,Express,Others

Place of Origin: China

Supply Ability: 10000 Pieces Monthly

Certificate: ISO9001

HS Code: 84029000000

Port: Shanghai Port,Ningbo Port,Qingdao Port

Payment Type: L/C,T/T,D/P,D/A,Paypal

Incoterm: FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP,DEQ,DDP,DDU,Express Delivery,DAF,DES

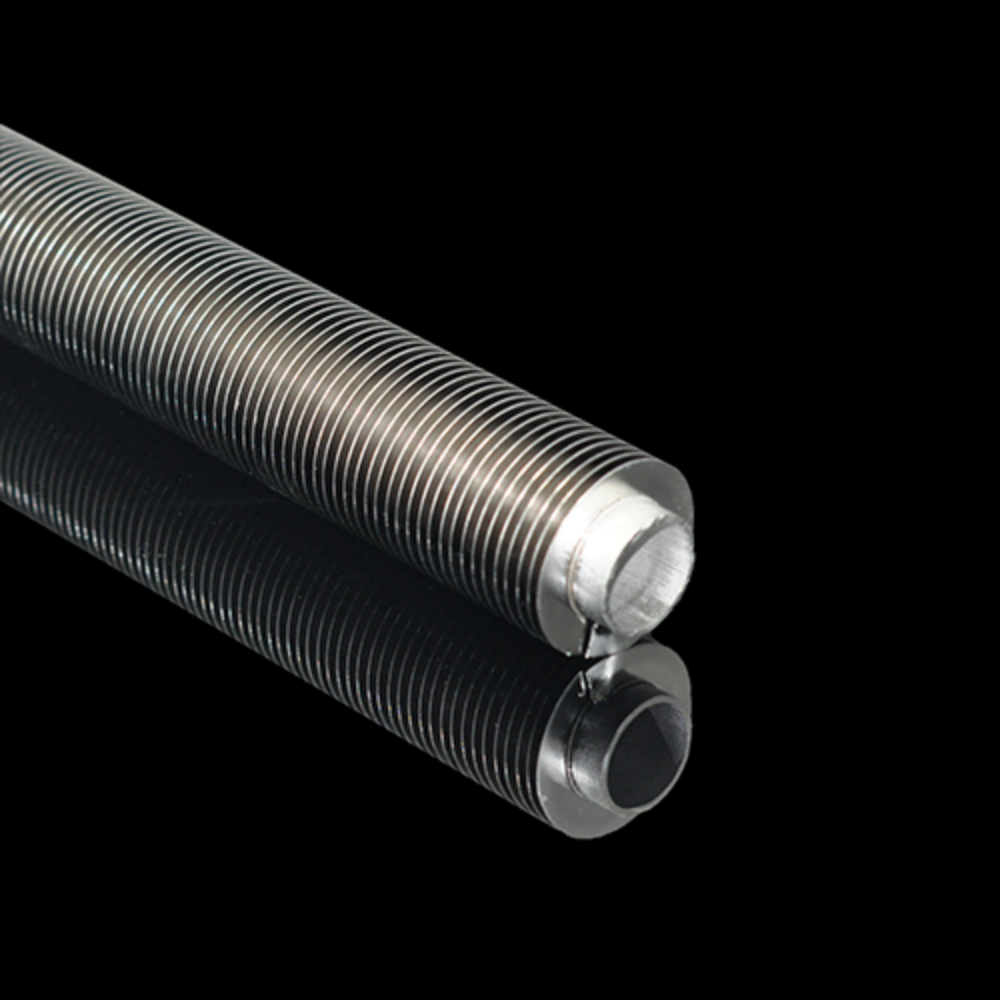

Laser Welded Finned Tube Product Description:

Laser welding finned tube is processed by laser welding machine. Laser welding is a welding method that irradiates a high-intensity laser beam onto the metal surface. Through the interaction of the laser and the metal, the metal absorbs the laser light and converts it into heat, melting the metal to form a cooling crystal. Laser welding machine is the most advanced laser welding equipment for finned tubes. Because the welding process is fully automatic and mechanical, the scientific and technological content and quality of laser welding finned tubes are superior to traditional cooling tubes.

The laser welding finned tube has a fully automatic welding process, saving manpower costs; secondly, the laser welding fin is firm, strong, and the test with high tensile strength is qualified. Laser welding is more efficient.

Laser Welding Fin Tube Manufacturing Process:

Laser welding is a high intensity laser beam to the metal surface, through the interaction of laser and metal, metal absorption laser into heat to make the metal melt after the formation of cooling crystallization welding.

Laser Welding Fin Tube(Welded Spiral Pipe) Advantages:

1.Laser welded finned tubes (fin tubes) finning machine has high automatic, the welding of fin to tubes and winding on tubes are made synchronously

2.100% welding rate, Laser welded fin tubes has strong soundness between fins and tubes, welding strength is over 600MPa.

3.Laser welded tube finning machine has high precision up to 0.05mm

4.0 contact resistance, high co-efficiency of heat transfer for spiral fin tubes by laser welding.

5.Save production cost. Laser welded finned tubes (fin tubes) has more small fin pitch, less than 2.5mm, its heat transfer area increase around 50% comparing to high frequency welded helical (spiral) finned tubes, which make material costs decrease largely as well as volume of Heat Exchanger.

Laser Welded Finned Tube(Stainless Steel Welded Pipes) Properties:

100% welding between fin and tube without using filler material.

No impurity of the weld seam, as the Laser-welding is carried out under a protective atmosphere

Different materials for fin and tube

Uncomplicated bending and coiling of the finned tube

No material deformation due to a small heat affected zone and thin weld seam, only slight microstructural change in tube and fin

Laser Welded Finned Tube(Stainless Steel Welded Pipe) Applications:

Right now the laser welded fin tube widely used in corrosive conditions, such as heat recovery in condensing boilers, and heat exchangers in Industries of Chemical, Petroleum, Petrochemical, Metallurgical, Power, Food and Maritime.

Laser Welded Finned Tube(Spiral Welding Pipe) Specifications:

Product Specification Tube OD 10~215 (mm) 0.4”~8.5” Tube Wall Thk 1~6 (mm) 0.04”~0.24” Tube Length ≤18,500 (mm) ≤60.7ft Fin Thk 0.3~2.0 (mm) 0.01”~0.08” Fin Height 3~30 (mm) 0.12”~1.2” Fin Pitch 2~20 (mm) 1~13 FPI Fin Type Solid, Serrated Material Combinations Fin Material S.S. C.S. Aluminum Copper Titanium Tube Material S.S. C.S. Copper Titanium Applied

Temperature 450°C Type of Service High temperature

Product Categories : Laser Welded Finned Tube

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.