Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Murphy Thermal Energy Co., Ltd.

Brand: Murphy

Applicable Industry: Hotels, Machinery Repair Shops, Manufacturing Plant, Food &Amp; Beverage Factory, Energy &Amp; Mining, Printing Shops, Food &Amp; Beverage Shops, Restaurant, Retail, Home Use

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Germany, Viet Nam, Philippines, Pakistan

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Ordinary Product

Place Of Origin: China

Species: Heat Exchanger Tube

Use: Heater Parts

Certification: Ul

Warranty Period: 1 Year

Service System: Online Support, Video Technical Support, Free Spare Parts

Packaging: Wooden Case

Productivity: 10000 piece

Transportation: Ocean,Land,Express,Air,Others

Place of Origin: China

Supply Ability: 10000 Piece

Certificate: ISO9001

HS Code: 8402900000

Port: Shanghai

Payment Type: L/C,T/T,Paypal,Western Union,Others

Incoterm: FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP,DDP,DDU,Express Delivery

Laser Welded Finned Tube Product Description:

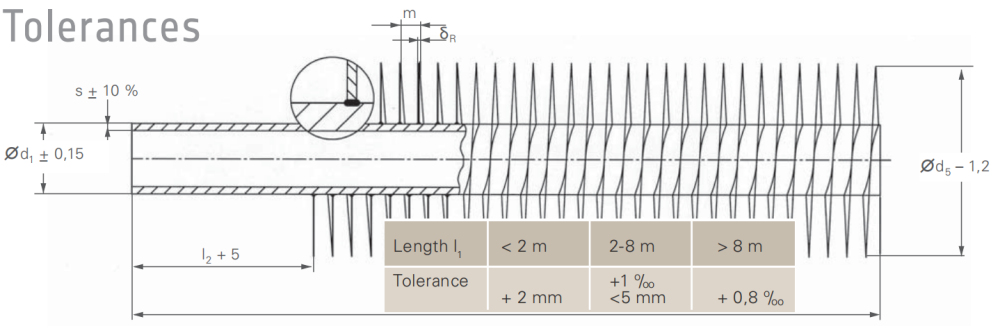

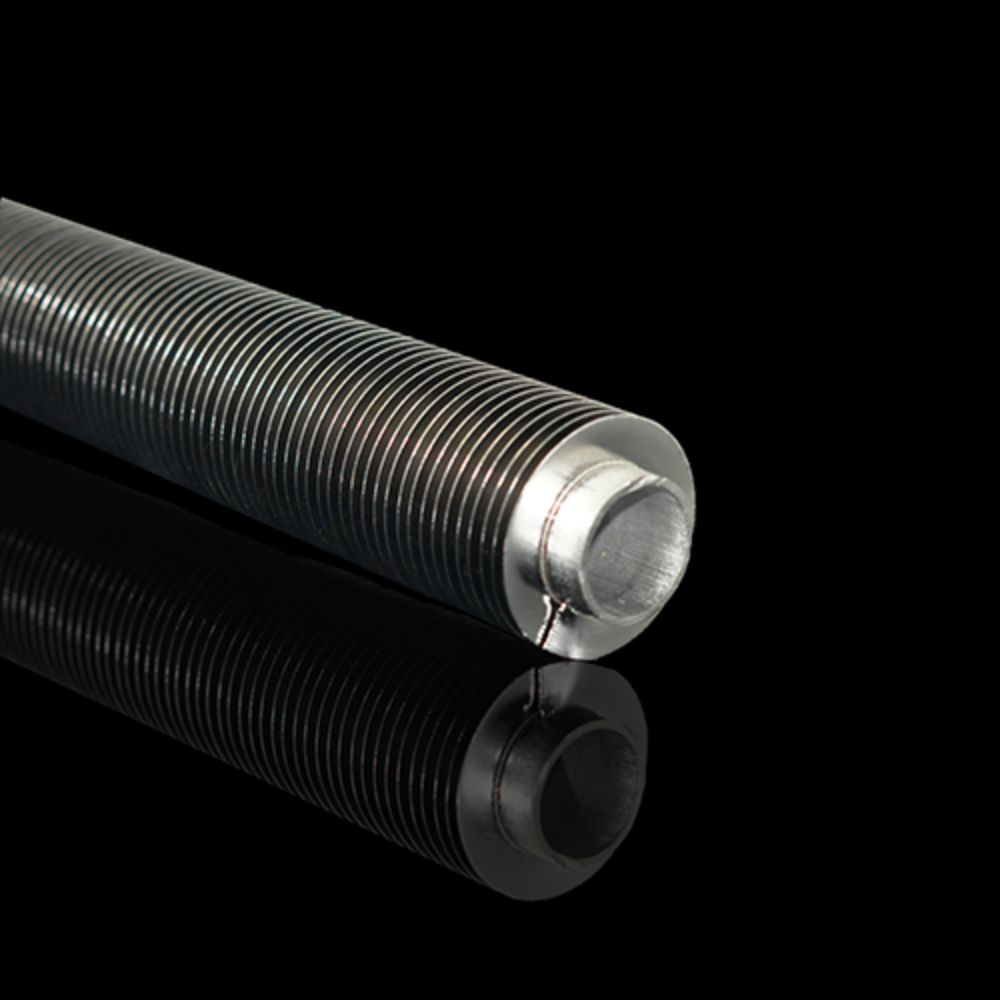

Laser Fin Tube are manufactured by helically winding strip onto tubes. The heat transfer fins are attached to the surface of tubing in a unique laser process within a protected atmosphere. This method produces high quality finned tubes in a process which is constantly being improved upon.Fin and tube material can be selected according to specific design requirements.The small heat-affected zone in connection with thin weld seams avoid any deformation of the material. This results in a high stability of shape and a great accuracy of size of the welded finned tube.

The use of Laser technique for the welding of finned tubes offers a number of advantages.

Laser Welding Fin Tube Manufacturing Process:

Laser welding is a high intensity laser beam to the metal surface, through the interaction of laser and metal, metal absorption laser into heat to make the metal melt after the formation of cooling crystallization welding.

Laser Welding Fin Tube(Welded Spiral Pipe) Advantages:

1.Highest Quality Product

The perfect bond between fin and tube improves efficiency in heat transfer and resistance to corrosion resulting in a clean weld fin to tube joint and fully straight fins (no corrugation).

2.New Material Combinations And Range Of Production

Our Laser Finning Process allows a wider dimensional range of tube and fin combinations. Feasible height, thickness and pitch of fins go way beyond any conventional finning process.

In addition, an increased range of material combinations of both tube and fin (steel, aluminum, copper, titanium) offers new advantages and alternatives to the industry.

3.Price Saving

Lower energy consumption, reduced cost of consumables and increased efficiency of the process allow us to offer very competitive prices.

Laser Welded Finned Tube(Stainless Steel Welded Pipes) Properties:

1.a high degree of automation, automatic fins laser welding machine can realize one-time completion of welding, synchronous winding make the fin foot and the pipe depth of weld.

2.laser welding, high firmness, high binding force. Laser welding is metallurgical bonding, welding strength is more than 600MPa.

3.laser welding machine with high accuracy, welding a 8 meter long fin tube with a precision of 0.05mm.

4.the heat transfer coefficient can be improved greatly by laser welding.

5.laser welding finned segment length is less than or equal to 2.5 mm, heat dissipation area than the high frequency welded pipe (distance is more than or equal to 4.5 mm) increased by nearly 50%, greatly reducing the material of the tube, also can decrease the change of the volume of the Heat Exchanger.

Laser Welded Finned Tube(Stainless Steel Welded Pipe) Applications:

Waste heat recovery in the power industry, metallurgy, and cement industries, as well as petrochemical industries

Laser Welded Finned Tube(Spiral Welding Pipe) Specifications:

Product Specification Tube OD 10~215 (mm) 0.4”~8.5” Tube Wall Thk 1~6 (mm) 0.04”~0.24” Tube Length ≤18,500 (mm) ≤60.7ft Fin Thk 0.3~2.0 (mm) 0.01”~0.08” Fin Height 3~30 (mm) 0.12”~1.2” Fin Pitch 2~20 (mm) 1~13 FPI Fin Type Solid, Serrated Material Combinations Fin Material S.S. C.S. Aluminum Copper Titanium Tube Material S.S. C.S. Copper Titanium Applied

Temperature 450°C Type of Service High temperature

Product Categories : Laser Welded Finned Tube

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.