Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Murphy Thermal Energy Co., Ltd.

Brand: Murphy

Applicable Industry: Manufacturing Plant, Food &Amp; Beverage Factory, Construction Works, Energy &Amp; Mining, Other

Out-of-warranty Service: Video Technical Support, Online Support

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Ordinary Product

Place Of Origin: China

Species: Fin Tube

Use: Heater Parts

Certification: Ul

Warranty Period: 1 Year

Service System: Free Spare Parts, Online Support

Packaging: wooden box

Productivity: 10000 Piece/Pieces per Month

Transportation: Ocean,Air,Express

Place of Origin: China

Supply Ability: TBD

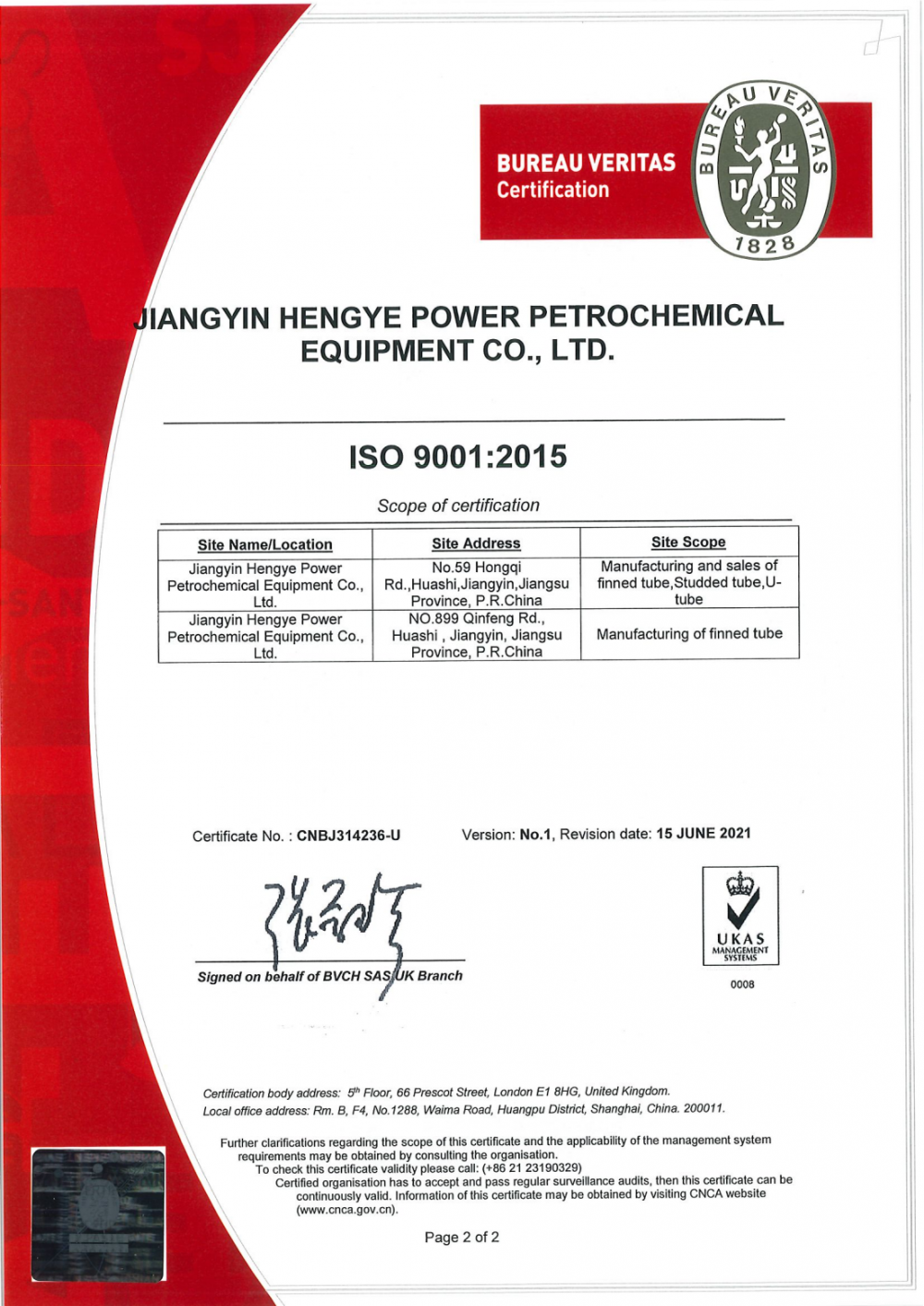

Certificate: ISO90001

HS Code: 8108904090

Port: Shanghai

Payment Type: T/T

Incoterm: FOB,EXW

Integral Low Finned Tube Product Description:

Low-finned tubes are a reliable solution for controlling the temperature of gases and liquids, or for evaporating and condensing refrigerants. Thanks to their larger heat transfer surface area, they offer considerable potential to save in terms of materials and fill volumes. The wide range of dimensions offered by Thermal Solutions makes these products perfect for a broad scope of applications in the refrigeration and air conditioning industry, for oil/gas coolers in machinery and plant engineering, and for intermediate vapor super heaters in process engineering.

Low Finned Tube Manufacturing Process:

Low fin (integral) tube is an extruded tube consisting of short low fins, the fins are rolled out from the outer wall of the plain tube by rollers, and the tube and fins are in the same piece of tube.

Integral Low Finned Tube(Copper Finned Tube) Advantages:

Combination of lower fin height and more fins per meter maintains the general ratio of 1:1 fin height to fin spacing.

Doesn’t require higher tube pitch therefore, doesn’t require shell size higher than shell of bare tube Heat Exchanger.

Improved heat transfer coefficient and rate of heat transfer as compared to conventional finned tube designs.

Compact design of heat exchanger having lesser weight and size.

Improved tube life.

Low Finned Tube(Aluminum Fin Tubes) Properties:

1.The processing cost is low;

2.The low-finned tube is formed by directly rotating the steel tube to form fins, so there is no need to worry about falling off even if it is bent later.

3.Has excellent durability and anti-vibration performance.

4.Increase the external surface area of the bare tube by 2.5-3 times, improve the efficiency of the heat exchanger, and improve the performance of the existing heat exchanger.

5.The reduction in space and weight is very valuable for offshore production or high altitude distillation columns. Low-fin technology can transform large shell and tube heat exchangers into compact heat exchangers

6.It has a wide range of applications and can strengthen the evaporation, condensation, gaseous heat transfer and liquid heat transfer of the medium on the shell side.

Integral Low Fin Tube(Finned Copper Tube) Applications:

Integral Fin Tubes can be used in various Heat Exchanger Applications, Viz. Condensers, Chillers, Oil Coolers and Shell & Tube type Heat Exchangers, etc.

Integral Low Fin Tube Specifications:

| Product Specification | ||

| Tube OD | 12.7~31.75 (mm) | 1/4”~1 1/4”(NPS) |

| Tube Wall Thk | 1.65~3.0 (mm) | 0.065”~0.118” |

| Tube Length | ≤18,500 (mm) | ≤60.7 ft |

| Fin Thk | 0.3~0.5 (mm) | 0.0118"~0.0197” |

| Fin Height | 0.9~1.3 (mm) | 0.0354”~0.0512” |

| Fin Pitch | 666~1111 FPM | 16~30 FPI |

| Fin Type | Integral Low | |

| Material | ||

| Tube Material | C.S., S.S., A.S., Copper, Titanium | |

| Applied Temperature | 415°C | |

Product Categories : Integral Low Finned Tube

Manufacturing Process

The fins are rolled out from the wall of the tubes and hence are integral with the tube. As the fins are formed from the base tube by rolling out material from its wall, the wall thickness under the finned section is reduced compared to the wall thickness at plain ends. These fin tubes can be manufactured from most tubular materials and the hardness of the material usually determines the finning code or fin profile. The harder materials such as Nickel Alloys, Stainless Steel, Titanium are supplied with higher density (i.e. 26, 28, 30 FPI). This shallow profile reduces the work hardening of the material and helps to eliminate the possibility of root fin cracking.

Whereas, softer materials like Carbon Steel, Copper, and Copper Alloys are supplied with deeper profile giving a lower fin density (i.e. 16 or 19 FPI). These tubes can also be supplied with intermediate plain landing as well as U bent, where U bend portion can be finned or un-finned.

Production Capacity

Total four (4) finning lines, monthly production capacity is 80,000 meters in total.

Properties

Manufacturing Process:- Cold Rolling of Fin on the Base tube Itself.

Fin To Tube Bond:- NA (fin is made from the base tube itself)

Heat Transfer Efficiency:- Good

Mechanical Resistance: – Good

Corrosion Protection: – Moderate

Temperature Range:- Up to Maximum 415 Deg C

Frequently Asked Questions (FAQ) About Integral low Finned Tubes:

1. What is the fin efficiency?

Fin efficiency is defined as the ratio of actual heat flow of the fin to that which would be obtained with a fin of constant temperature uniformly equal to the base surface temperature, that is, one with infinite thermal conductivity.

2. What are low finned tubes?

Low Finned tube is a finned tube obtained through plastic cold deformation. The method consists in realizing, from a smooth tube, fins with a particular geometric form without removing material; this plastic deformation causes an increment of heat exchange efficiency, and allows to reduce the heat exchanger size.

3. How are low fin tubes made?

Low finned tubes involve rotational processing of the outer surface of steel tubes to create a fin shape. A steel pipe length of 25.4 mm (1 inch) per fin and 19 fins is a design often used. We can also produce units with 26 fins.

4. What are advantages of integral low finned tubes?

Provides 2.5 to 3 times the external surface area of bare tube

Reduced capital cost for new equipment

Reduced retrofitting cost for existing equipment

Space, weight & structural savings

More materials & alloys to select

Reduced maintenance & life cycle cost

5. Where are integral low finned tubes used?

Low finned tubes are a reliable solution for controlling the temperature of gases and liquids, or for evaporating and condensing refrigerants. Thanks to their larger heat transfer surface area, they offer considerable potential to save in terms of materials and fill volumes, especially applicable to air and other gases on the fin-side and a fluid on the tube-side. Applied in heat exchanger for oil refinery and petrochemical plants, condenser and heat exchanger for petrochemical plants, condenser & evaporator for power plants.

6. How do you control your quality?

We always put quality as the most important thing for customers, and we control the quality from raw material inspection, production checking to water pressure test and strength test. Also the third party can be authorized to check.

Incoming inspection report for bare tube & strip.

Mill test certification for bare tube

Mill test certification for fin

Mill test certification for finned tube

Finned tubes dimension & visual inspection reports

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.