Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Murphy Thermal Energy Co., Ltd.

Model No.: murphy-61

Brand: Murphy

Status: New

Applicable Industry: Food &Amp; Beverage Factory, Manufacturing Plant, Retail, Energy &Amp; Mining, Other

Out-of-warranty Service: Online Support

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Ordinary Product

Place Of Origin: China

Species: Fin Tube

Use: Heater Parts

Certification: Ul

Warranty Period: 1 Year

Service System: Online Support

Packaging: wooden box

Productivity: 10000 Piece/Pieces per Month

Transportation: Ocean,Air,Express

Place of Origin: China

Supply Ability: TBD

Certificate: ISO90001

HS Code: 8108904090

Port: Shanghai

Payment Type: T/T

Incoterm: FOB,EXW

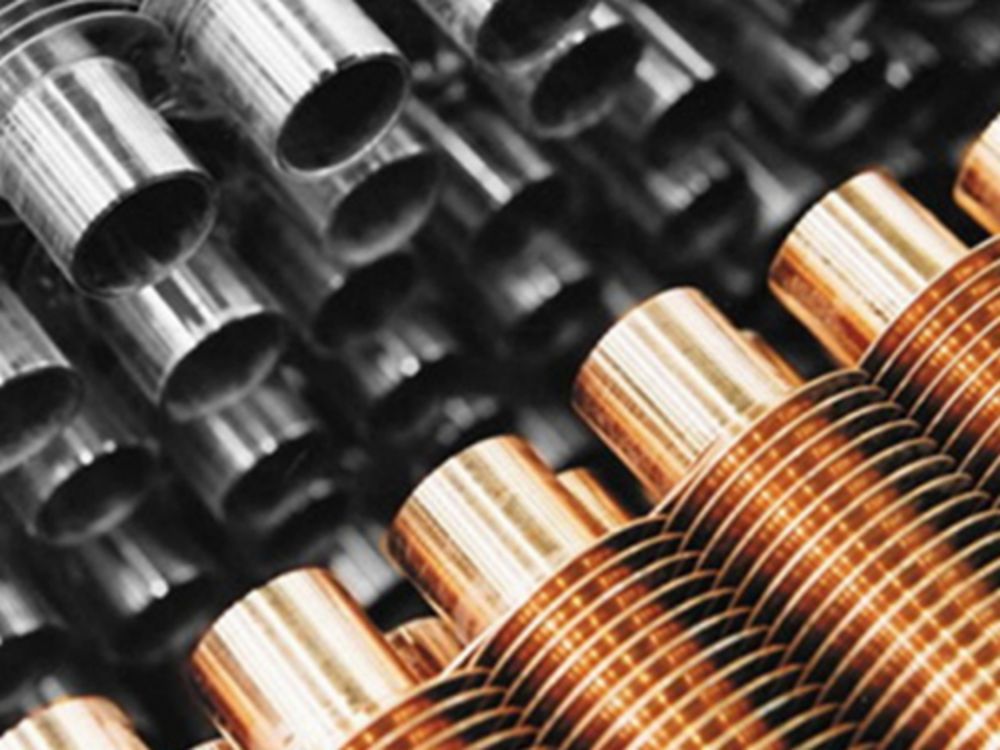

High Frequency Welded Fin Tube Product Description:

Helical Fin Tube are manufactured in both Solid and Serrated win profiles.

Helical Serrated Finned Tubes are manufactured by helically wrapping continuous serrated fin strip on edge around the tube circumference and consistence welding the fin strip to the tubes. Before being formed around the tube, the fin strip is serrated crosswise from one edge to within 6.35mm of the other edge, leaving an uncut portion that will become a continuous base for the fin segments. The edge will become the outer edge of the fin segments. The interval between cuts (which determines the segment width after the strip is formed around the tube) may be specified as either 4mm or 8mm. After being cut, the fin strip is held under tension and confined laterally as it is formed around the tube, thereby ensuring forceful contact with the tube surface. The fin strip is wounded spirally onto the tube and welded continuously with a High Frequency Electrical process to the tube along the spiral root. As the fin strip is formed around the tube its outer (serrated) edge spreads, opening the segments like petals of a daisy. A consistence weld is applied at the point where the fin strip first begins to bend around the tube diameter, using the gas metal arc welding process.

The strong connection between fin and base tube prevents loosening of fin because of heat stress, oxidization, corrosion etc., use at very high temperatures possible. This welded steel finned tubes configuration can be used in practically any heat transfer applications, and particularly suited for high temperature, high pressure applications. The important features of this configuration are efficient, effective bond of fin to tube under any conditions of temperature and pressure, and ability to withstand high fin-side temperatures.

High Frequency Finned Tube Manufacturing Process:

The steel fin (solid or serrated) is helical wound and continuously welded to the tube by high frequency electric resistance welding. This produces a homogeneous, clean and continuous fin-to tube bond with no additional weld material, for a very efficient heat flow and resistance to corrosion.

The welding process enables the combination of any grades for studs and tube: carbon, alloy, stainless steels and high nickel alloys. Alloy steel pipes are stress-relieved after studding, according to the relevant specifications for the class and grade of steel used.

High Frequency Welded Fin Tube(Electric Resistance Welded Pipe) Advantages:

1.Simple and economical installation High frequency welding spiral fin tube are with zero connection point, so that the installation is more economical, fast, and reduce the probability of leakage at the joint.

2. Easy maintenance. After installation, high-frequency welded spiral fin tube doesn’t need additional maintenance.

3. High efficiency High frequency welding spiral fin tube is full contact welding between fin and steel tube whose heat dissipation area is more than 8 times of bare tube. In addition, the smooth internal wall reduces water flow resistance as well.

4. Long service life, Fin and pipes are combined with high mechanical strength whose tensile strength is more than 200 Mpa. Both inside and outside of the tube are treated with hot dip galvanized processing.

High Frequency Welded Fin Tube(Welded Aluminum Pipe) Properties:

Manufacturing Process:- Continuously Welded Spiral Fin Tube

Fin To Tube Bond:- Excellent

Heat Transfer Efficiency:- Excellent

Mechanical Resistance:- Excellent (Hence can be frequently cleaned with high pressure jets unlike other fin tubes. Thereby reducing down time and increasing overall life)

Corrosion Protection:- Moderate

Temperature Range:- Up to Maximum 500 Deg C

High Frequency Welded Fin Tube(Spiral Welded Pipe) Applications:

Widely used in waste heat recovery, petrochemical industry, power plant boiler, economizer, coaches, civil building heating, refrigerating, drying, medicine of wood drying, food drying system and other industries.

High Frequency Welded Fin Tube(Spiral Welded Pipes) Specifications:

| Product Specification | ||

| Tube OD | 16~273 (mm) | 3/8”~10”(NPS) |

| Tube Wall Thk | 2~28.6 (mm) | 0.08”~1.1” |

| Tube Length | ≤28,000 (mm) | ≤92 ft |

| Fin Thk | 0.5~3.5 (mm) | 0.02”~0.14” |

| Fin Height | 8~35 (mm) | 0.31”~1.3” |

| Fin Pitch | 3~333 FPM | 1~8 FPI |

| Fin Type | Solid, “U”or"V” Serrated | |

| Material Combinations | ||

| Fin Material | C.S. (most common grade: 08F) | |

| S.S. (most common grade are AISI 304, 316, 409, 410, 321,347,2205) | ||

| A.S. | ||

| Tube Material | C.S. (most common grade: A106 Gr.B) | |

| S.S. (most common grade are TP304,316, 321, 347) | ||

| A.S. (most common grade are T/P5,9,11,22,91) | ||

| Applied Temperature | 500°C | |

| Type of Service | High temperature | |

Product Categories : High Frequency Welded Fin Tube

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.