Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Murphy Thermal Energy Co., Ltd.

Brand: Murphy

Status: New

Applicable Industry: Machinery Repair Shops, Manufacturing Plant, Energy &Amp; Mining, Other

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Ordinary Product

Place Of Origin: China

Species: Fin Tube

Use: Heater Parts

Certification: Ce

Warranty Period: 1 Year

Service System: Free Spare Parts, Video Technical Support, Online Support

Packaging: wooden box

Productivity: 10000 Piece/Pieces per Month

Transportation: Ocean,Air,Express

Place of Origin: China

Supply Ability: TBD

Certificate: ISO90001

HS Code: 8108904090

Port: Shanghai

Payment Type: T/T

Incoterm: FOB,EXW

High Frequency Welded Fin Tube Product Description:

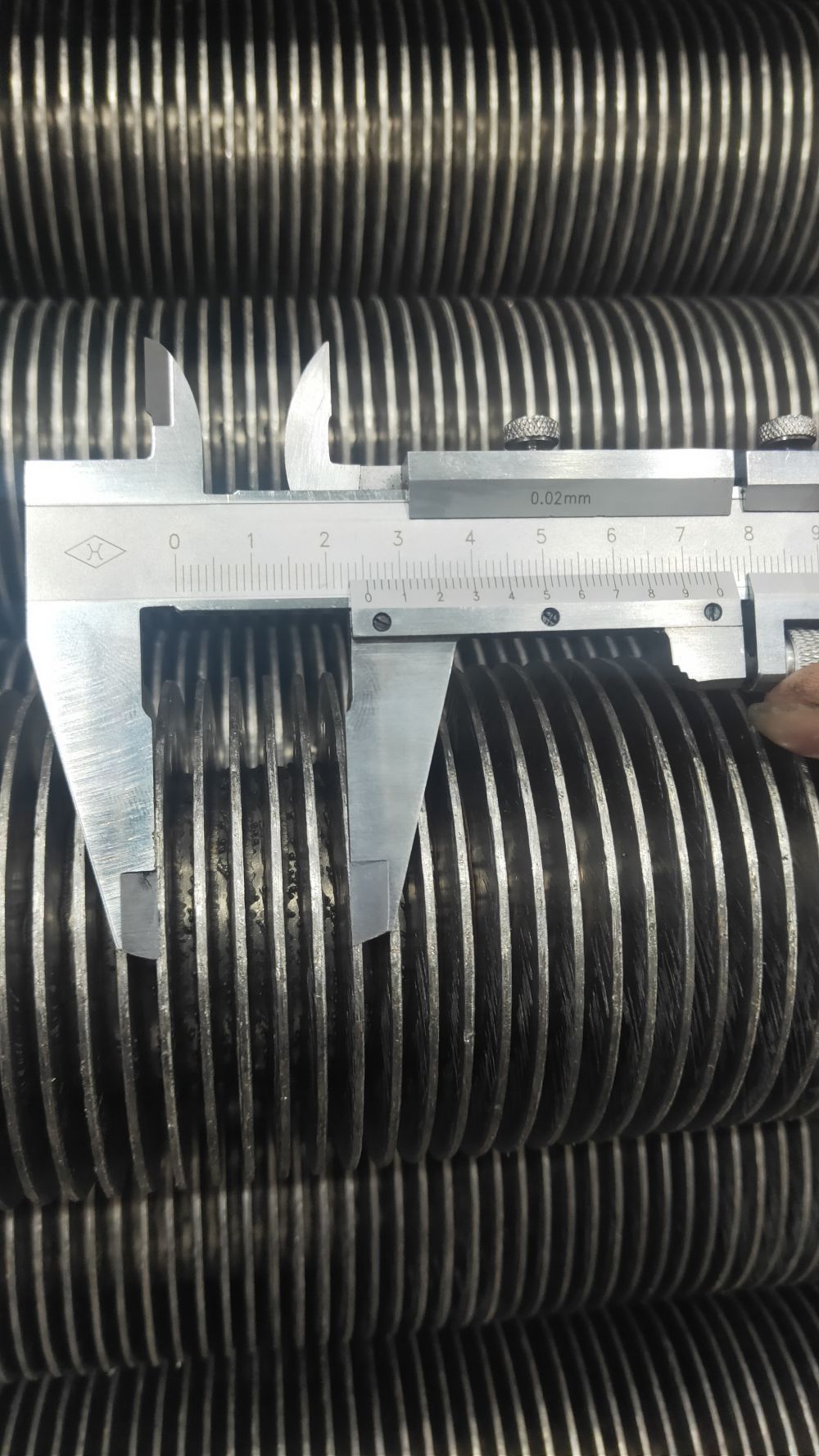

Welded Helical Solid Fin Tube are manufactured with by helically wrapping fin strip on edge around the tube circumference and continuously welding the fin strip to the tube. The fin strip is held under tension and confined laterally as it is formed around the tube, thereby ensuring that the strip is in forceful contact with the tube surface. A continuous weld is applied at the point where the fin strip first begins to bend around the tube diameter using unique gas metal arc welding process. This weld process creates the strongest fin to tube attachment in the industry, excellent heat transfer characteristics, low fin-side pressure drop and little to no change in grain micro structure and physical characteristics even when 3%-9% chromium tubes are used.

For a given pipe or tube size, the desired heat transfer surface area per unit length of tube can be obtained by specifying the appropriate fin height, fin thickness and number of fins per inch.

This solid fin configuration can be used for practically any heat transfer application, and is particularly suited to high temperature, high pressure applications with high fin-side temperatures. Solid fin can be supplied with thicker fins than the serrated fin, which can be an important factor when dealing with extremely corrosive or erosive environments. Solid fin is typically the fin configuration of choice where severe service environment is expected, or when dealing with fibrous or sticky fluids, which can cause fouling and repeated cleanings.

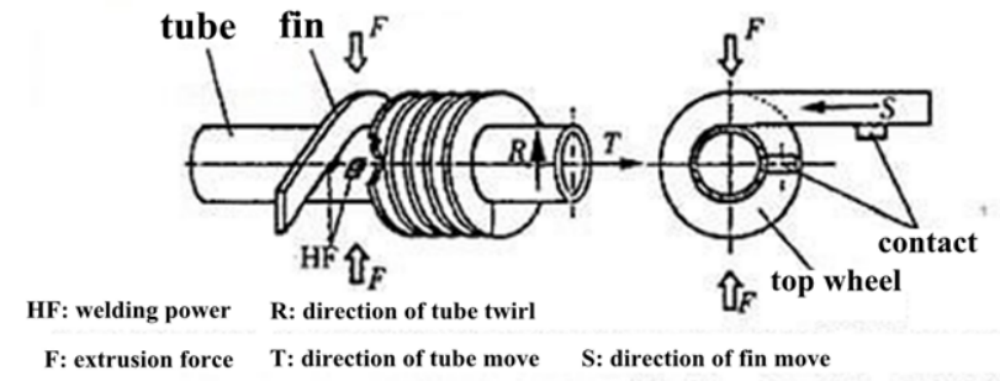

High Frequency Finned Tube Manufacturing Process:

The High Frequency Resistance Welding process usually employs 400, 000 Hz current. With this technique, the fin is wound on edge around the tube spirally and a continuous weld is obtained.

The High Frequency Resistance Welding process produces a strong metallurgical bond between the fin and the tube while minimizing the heat affected zone (HAZ) in the tube.

High Frequency Welded Fin Tube(Electric Resistance Welded Pipe) Advantages:

1. Higher heat transfer coefficient. The serrate can make the gas flow across the fins freely, enhancing the turbulent motion and improving the heat transfer effect. Researches show that serrated fin tube’s heat transfer efficiency is about 15-20% higher than common solid fin tube.

2. Reduce metal consume. Due to the higher heat transfer coefficient, for the same amount of heat, serrated fin tube is with less heat transfer areas, which help reduce the metal consume.

3. Anti-ash-deposition and anti-scaling. Due to the serrate, it is very hard for the serrated fin tube to deposit the ash and scaling.

4. It is more flexible to adapt to the changes of gas flow direction.

High Frequency Welded Fin Tube(Welded Aluminum Pipe) Properties:

Manufacturing Process:- Continuously Welded Spiral Fin Tube

Fin To Tube Bond:- Excellent

Heat Transfer Efficiency:- Excellent

Mechanical Resistance:- Excellent (Hence can be frequently cleaned with high pressure jets unlike other fin tubes. Thereby reducing down time and increasing overall life)

Corrosion Protection:- Moderate

Temperature Range:- Up to Maximum 500 Deg C

High Frequency Welded Fin Tube(Spiral Welded Pipe) Applications:

High Frequency Welded Fin Tubes are used in Heat Recovery Systems associated with Furnaces for Petrochemicals applications, and with Boilers for Power Generation and Waste Heat Recovery applications. The usage of finned tubes in Heat Exchangers reduce cost and size of the equipment which directly results in performance improvement.

High Frequency Welded Fin Tube(Spiral Welded Pipes) Specifications:

| Product Specification | ||

| Tube OD | 16~273 (mm) | 3/8”~10”(NPS) |

| Tube Wall Thk | 2~28.6 (mm) | 0.08”~1.1” |

| Tube Length | ≤28,000 (mm) | ≤92 ft |

| Fin Thk | 0.5~3.5 (mm) | 0.02”~0.14” |

| Fin Height | 8~35 (mm) | 0.31”~1.3” |

| Fin Pitch | 3~333 FPM | 1~8 FPI |

| Fin Type | Solid, “U”or"V” Serrated | |

| Material Combinations | ||

| Fin Material | C.S. (most common grade: 08F) | |

| S.S. (most common grade are AISI 304, 316, 409, 410, 321,347,2205) | ||

| A.S. | ||

| Tube Material | C.S. (most common grade: A106 Gr.B) | |

| S.S. (most common grade are TP304,316, 321, 347) | ||

| A.S. (most common grade are T/P5,9,11,22,91) | ||

| Applied Temperature | 500°C | |

| Type of Service | High temperature | |

Product Categories : High Frequency Welded Fin Tube

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.