Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Murphy Thermal Energy Co., Ltd.

Brand: Murphy

Status: Used

Applicable Industry: Food Shop, Printing Shops, Building Material Shops, Retail, Construction Works, Machinery Repair Shops, Energy &Amp; Mining, Manufacturing Plant, Food &Amp; Beverage Shops, Food &Amp; Beverage Factory, Other, Farms, Advertising Company, Restaurant, Home Use

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Pakistan, Viet Nam, Philippines

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Pakistan, Viet Nam, Philippines

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Ordinary Product

Place Of Origin: China

Species: Heat Exchanger Tube

Use: Heater Parts

Certification: Ce

Warranty Period: 1 Year

Service System: Free Spare Parts, Video Technical Support, Online Support

Packaging: Wooden Case

Productivity: 10000 Pieces Monthly

Transportation: Ocean,Land,Air,Express,Others

Place of Origin: China

Supply Ability: 10000 Piece Monthly

Certificate: ISO9001

HS Code: 7306400000

Port: Shanghai Port,Qingdao Port,Ningbo Port

Payment Type: L/C,T/T,D/P,D/A,Paypal,Money Gram,Western Union

Incoterm: FOB,CFR,CIF,EXW,FAS,FCA,CIP,DEQ,DDU,Express Delivery,DAF,DES,DDP

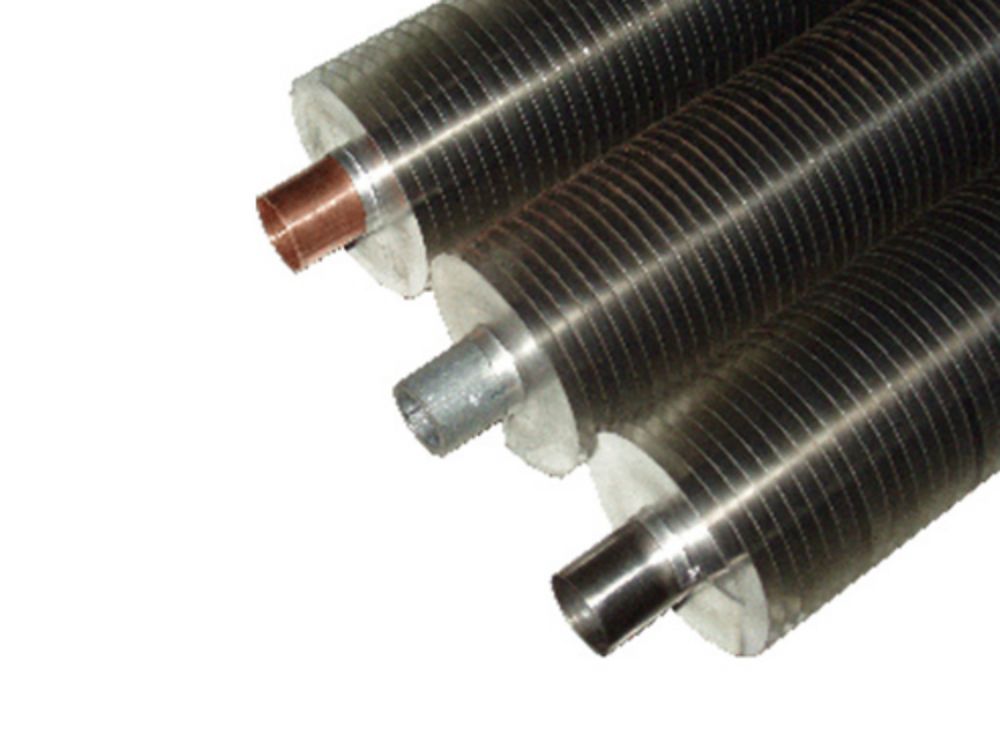

L/LL/KL Finned Tube Product Description:

- LL Finned Tube(Double L/Overlapped L)

The LL-Foot type fin is commonly known as double L or overlapped L fin, are used in applications where temperatures do not exceed about 350 degrees Fahrenheit The fins are manufactured from strip in similar to the L type except that the foot is preformed into an accurately controlled stepped double L shape, rolled into a taper which causes it to curl. It is then continuously helically wound under tension onto a tube. The fin hugs the tube with one fin overlapping the foot of the next fin with complete coverage of the base tube. This gives good corrosion protection to the tube. This type of tube is often used as an alternative to the more expensive extruded type fin in corrosive environments. The fins are secured at each end in a similar way as L fin.

- KL Finned Tube(Knurled Aluminum Tubing)

The KL fin is also known as the knurled L fin. This finned tube is almost identical to the Wrap-On fin and is made using both Wrap-On and Embedded techniques. The fins are made from strips that have been prepared into a L shape that is comparable to the L type, then rolled into a taper that causes it to curl. It is then helically wound onto the tube in a continuous loop under tension. The tube is hugged by the fin. A spinning tool knurls the base tube, and then the foot of the fin is knurled into the knurling of the base tube, resulting in a tight bond and improved thermal performance.

The foot of one fin bumps up against the next fin if the correct fin strip is utilised, and there is no space between the fins. This helps to protect the tube from corrosion. In a similar way to L fins, the fins are attached at each end to prevent unwinding. In applications involving metal, KL -Foot tension wound finned tubes are typically employed. Up to 320°C (608°F) maximum operating temperature

- L Finned Tube(Wrap-On Fin)

L-Foot Tension Wound Finned Tubes also known as Wrap-On Finned Tubes, are used in applications where temperatures do not exceed about 300 degrees Fahrenheit in other words for low-temperature application where some degree of tube wall protection is required. L-Foot tension wound finned tubes consist of thin aluminium fin strip tightly wound helically around the tube circumference. A “foot” is first formed on one side of the fin strip (hence the name L-Foot). The strip is then wound tightly around the tube, with the foot bearing on the tube outer surface. The short horizontal limb of each L is in contact with the base-tube surface to cover it completely. Tension in the fin strip as it is wrapped around the tube serves to seat the fin foot forcefully on the tube, and to hold the fin firmly in place. L-footed finned tubing offers maximum heat transfer at lower temperatures. The unique L-shaped design holds fins rigidly to withstand heat cycling and high velocity air vibration. This fin offers a certain degree of atmospheric protection of the tube wall against corrosion. The broad contact surface between the tube and the finning enhances heat transfer. This fin design is highly efficient yet cost effective.

The ends of the fins are stapled to prohibit the aluminium fin from unravelling, and loosing the contact between the fin foot and the tube. This contact is critical to the operation of the air cooler, since the heat is transferred from the tube wall, through the fin, to the surrounding ambient air.

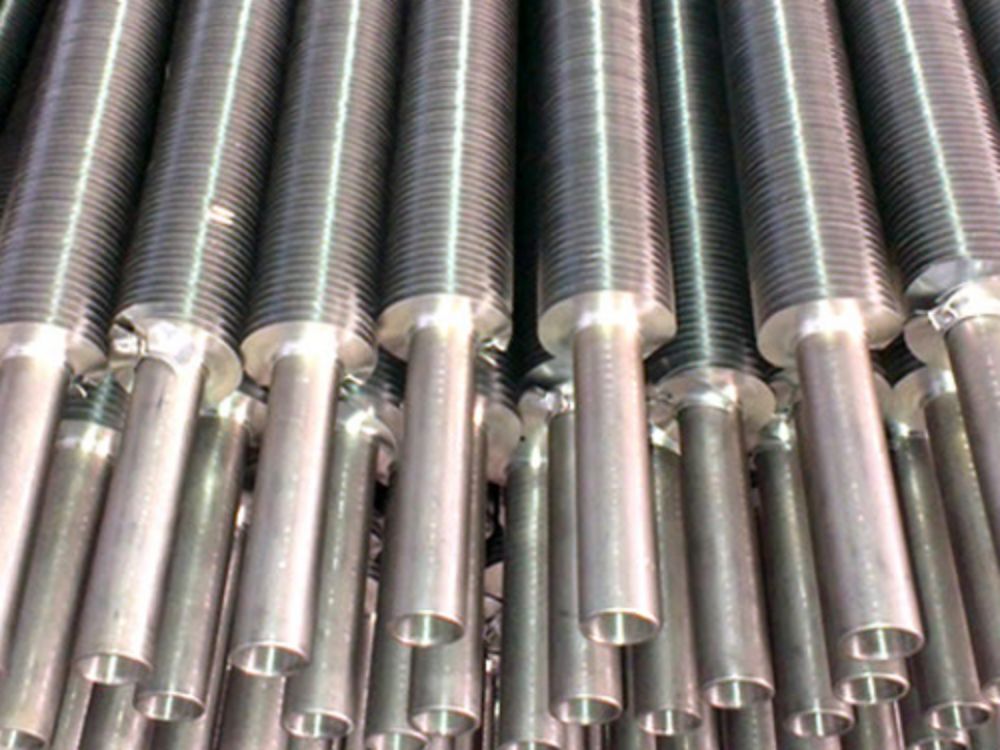

L/LL/KL Finned Tube(Knurled Aluminum Tube) Manufacturing Process:

Applied Fin Tube is made with strip wrapped under tension around the base of the tube. Fins are welded to the base tube at the strip ends.

L/LL/KL Finned Tube(Aluminum Finned Tubes) Advantages:

Core tube extensively protected against corrosion by the fin foot, finning of very thin-walled tubes possible.

L/LL/KL Finned Tube Properties:

Atmospheric Corrosion Resistance: OK

Mechanical Resistance: Poor

Fin Contact: Interference Fit

Fin To Tube Bond :Moderate

Heat Transfer Efficiency :Moderate

L/LL/KL Finned Tube Applications:

. the petroleum, chemical and petrochemical process industries

. natural gas treatment

. the steel industry: blast furnace and converter systems

. power generation: steam turbine exhaust condensing

- contact condensing with cooling of circulating condensate

- fossil and nuclear power plants

. air conditioning (Freon, ammonia, propane)

. incineration of household refuse

. compressor coolers, etc.

L/LL/KL Finned Tube Specifications:

| Product Specification | ||

| Tube OD | 19~51 (mm) | 3/8”~2” |

| Tube Wall Thk | 1.65~3.0(mm) | 0.065”~0.118” |

| Tube Length | ≤18,500 (mm) | ≤60.7 ft |

| Fin Thk | 0.3~0.5 (mm) | 0.012”~0.02” |

| Fin Height | 10~16 (mm) | 0.394”~0.63” |

| Fin Pitch | 100~433 FPM | 3~11 FPI |

| Fin Type | L,LL,KL | |

| Material Combinations | ||

| Fin Material | Aluminum (most common grade:Alu.1100, Alu.1060, Alu. 6063) | |

| Copper | ||

| Tube Material | C.S. (most common grade: A179, A192,SA210 GrA1/C,A106 Gr B ) | |

| S.S. (most common grade: TP304, 316) | ||

| Copper (most common grade:UNS12200,14200, 70600, CuNi70/30, CuNi 90/10) | ||

| Titanium (most common grade: B338Gr2) | ||

| Applied Temperature | L Type:150°CL,LL Type:180°C,kL Type:260°C | |

| Type of Service | L Type:Low temperature LLType:Low temperature, corrosive atmospheric environment applications KL Type:Medium temperature | |

Product Categories : L/LL/KL Finned Tube

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.