Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Murphy Thermal Energy Co., Ltd.

Brand: Murphy

Status: Used

Applicable Industry: Machinery Repair Shops, Manufacturing Plant, Food &Amp; Beverage Factory, Retail, Printing Shops, Construction Works, Energy &Amp; Mining, Food &Amp; Beverage Shops

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Viet Nam, Philippines, Pakistan

Showroom Location (in Which Countries Are There Sample Rooms Overseas): Viet Nam, Philippines, Pakistan

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Ordinary Product

Place Of Origin: China

Species: Heat Exchanger Tube

Use: Heater Parts

Certification: Ce

Warranty Period: 1 Year

Service System: Free Spare Parts, Video Technical Support, Online Support

Packaging: Wooden Box

Productivity: 10000 Pieces Monthly

Transportation: Ocean,Land,Air,Express,Others

Place of Origin: China

Supply Ability: 10000 Pieces Monthly

Certificate: ISO9001

HS Code: 84029000000

Port: Shanghai Port,Ningbo Port,Qingdao Port

Payment Type: L/C,T/T,D/P,D/A,Paypal

Incoterm: FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP,DEQ,DDP,DDU,Express Delivery,DAF,DES

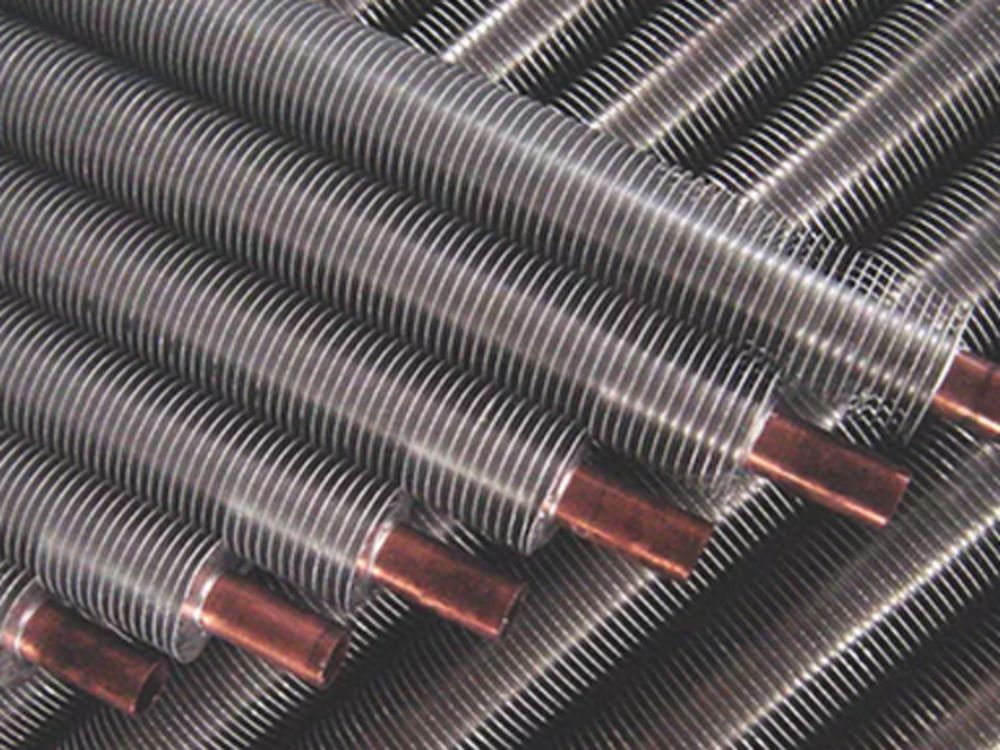

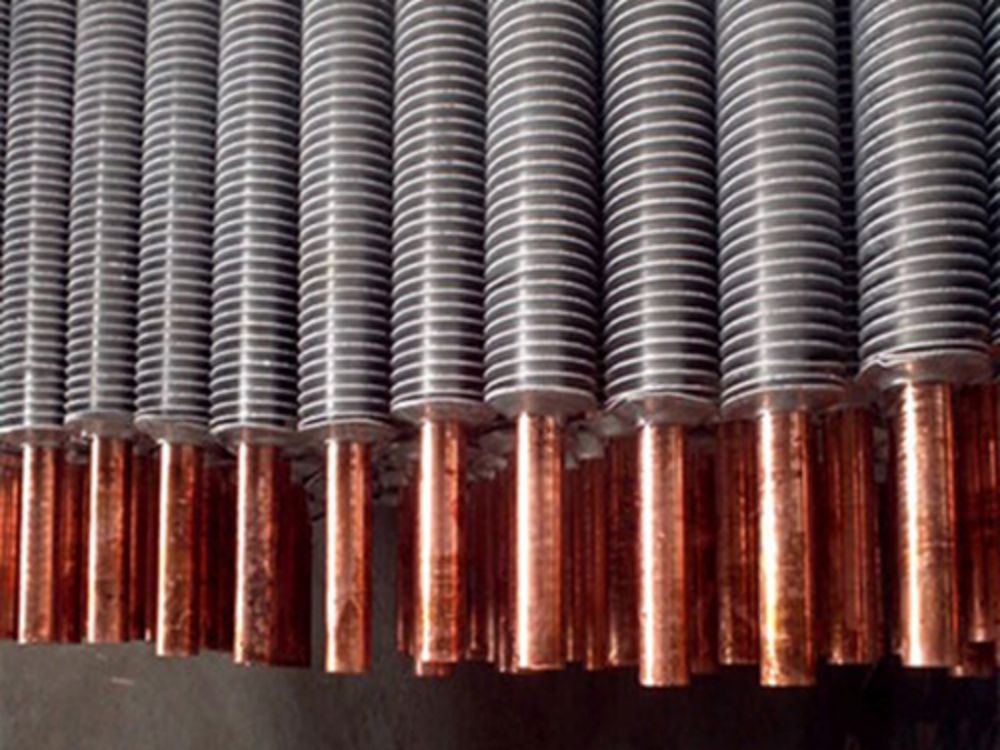

Extruded Fin Tube Product Description:

Bimetallic Extruded Fin Tube, use base tube insert Aluminium tube, directly extruded the Aluminium into wanted fin specification. Fin and tube surface are tight touch thus improving the heat transfer efficiency. This also give considerable corrosion protection to the base tube.

Extruded Finned Tube Manufacturing Process:

The Extruded Fin Tubes are produced by compressing an aluminum tube, or sleeve, onto the base tube. The bloom is exposed to very high pressures which essentially "grows" the fins into the final fin profiles.This process manufacture an excellent strong joint with great resistance (fin stiffness) as well as exceptional heat transfer capabilities (longevity, temperature range). The advantage of extruded fin tubes are full protection of bare tube against corrosion and fin has high mechanical strength. Extruded finned tubes provide the most stable performance over time as compared to the other fin types. The fin is rolled from an outer aluminum tube by a process using pressure to create a rolled "pressure bond" between the liner tube and fins. The aluminum fin material completely encloses the tube, except at the ends where a tube coating can be applied.

Extruded Fin Tubes Advantages:

1) Thermal

The bonding of the outer and inner tubes removes the risk of loss of contact with the aluminium due to thermal stress.

Maximum operating temperature: 250°C. The transfer coeffcient remains steady. Additionally as the outer sleeve is continuous no electrolytic couple is created.

2) Mechanical

The fins are more rigid and stand the handling shocks better,compared to types "G" an "L".

Extruded Aluminum Tubing Properties:

Manufacturing Process:- Cold Extrusion

Fin To Tube Bond:- Excellent

Heat Transfer Efficiency:- Excellent

Mechanical Resistance:- Excellent (Hence can be frequently cleaned with high pressure jets unlike other fin tubes. Thereby reducing down time and increasing overall life)

Corrosion Protection:- Gives excellent corrosion protection to the base tube since it entirely covers the base tube (except bare ends).

Temperature Range:- Upto Maximum 300 Deg C

Aluminum Extruded Tubing Applications:

the petroleum, chemical and petrochemical industries

natural gas treatment

the steel industry: blast furnace and converter cooling systems

power generation: steam turbine exhaust condensing

– contact condensing with cooling of circulating condensate

– fossil and nuclear power plants

air conditioning (freon, ammonia, propane)

incineration of household refuse

compressor coolers, ect.

Extruded Aluminum Tube Specifications:

| Product Specification | ||

| Tube OD | 10~51 (mm) | 0.4”~2” |

| Tube Wall Thk | 1.65~3.0 (mm) | 0.065”~0.118” |

| Tube Length | ≤18,500 (mm) | ≤60.7 ft |

| Fin Thk | 0.3~1.2 (mm) | 0.012”~0.047” |

| Fin Height | 5~16 (mm) | 0.2”~0.63” |

| Fin Pitch | 100~555 (mm) | 3~14 FPI |

| Fin Type | Extruded | |

| Material Combinations | ||

| Fin Material | Aluminum (most common grade:Alu.1100, Alu.1060, Alu. 6063) | |

| Copper | ||

| Tube Material | C.S. (most common grade: A179, A192,SA210 GrA1/C,A106 Gr B ) | |

| S.S. (most common grade: TP304, 316, 321, 347,A789) | ||

| Copper (most common grade:UNS12200,14200, 70600, CuNi70/30, CuNi 90/10) | ||

| Titanium (most common grade: B338Gr2) | ||

| Applied Temperature | 300°C | |

| Type of Service | Medium temperature, severe atmospheric corrosive environment. | |

Product Categories : Extruded Finned Tube

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.