Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Murphy Thermal Energy Co., Ltd.

Brand: Murphy

Status: New

Applicable Industry: Machinery Repair Shops, Manufacturing Plant, Energy &Amp; Mining, Other

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Ordinary Product

Place Of Origin: China

Species: Fin Tube

Use: Heater Parts

Certification: Ce

Warranty Period: 1 Year

Service System: Free Spare Parts, Video Technical Support, Online Support

Packaging: wooden box

Productivity: 10000 Piece/Pieces per Month

Transportation: Ocean,Air,Express

Place of Origin: China

Supply Ability: TBD

Certificate: ISO90001

HS Code: 8108904090

Port: Shanghai

Payment Type: T/T

Incoterm: FOB,EXW

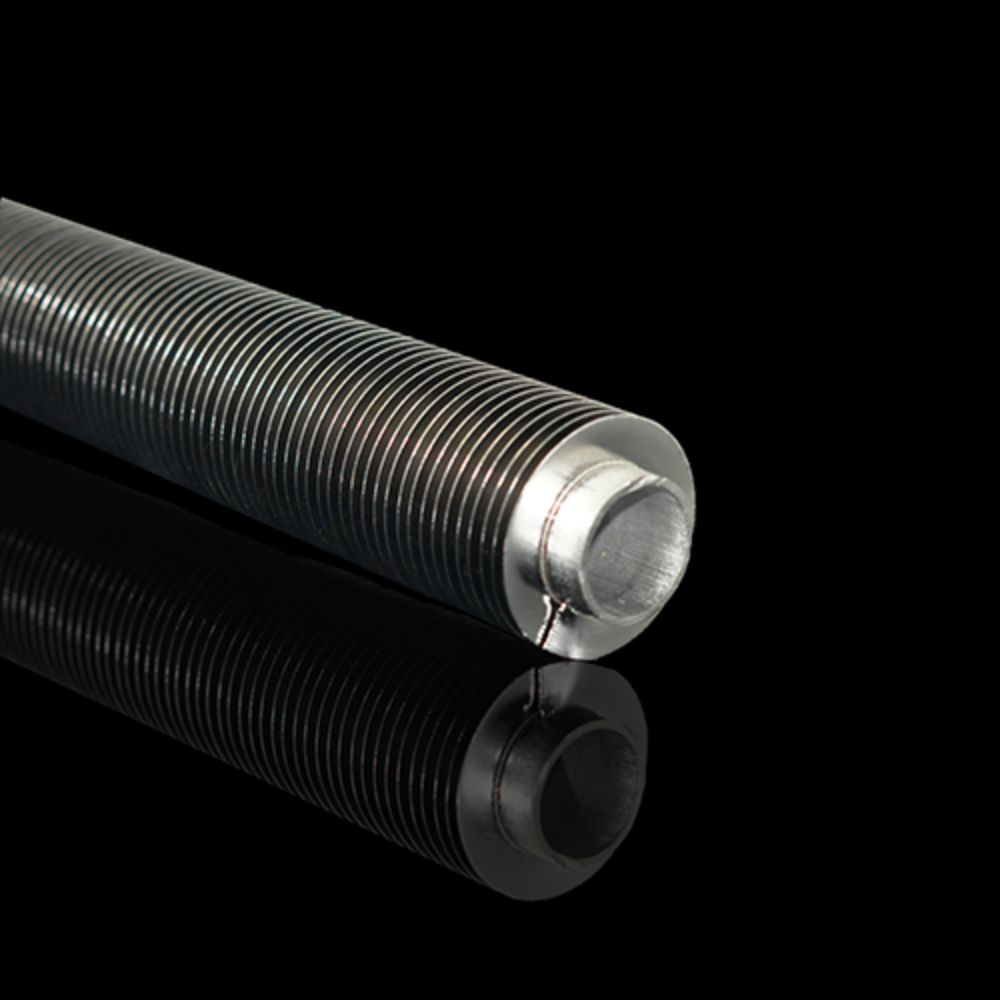

Laser Welded Finned Tube Product Description:

100% welding between fin and tube without using filler material. No impurity of the weld seam, as the laser welding is carried out under a protective atmosphere.

Laser Welding Fin Tube Manufacturing Process:

Laser welding is a high intensity laser beam to the metal surface, through the interaction of laser and metal, metal absorption laser into heat to make the metal melt after the formation of cooling crystallization welding.

Laser Welding Fin Tube(Welded Spiral Pipe) Advantages:

1.The thickness of base tube and fin can be 0.8-1.5 mm and 0.3-1 mm respectively, which greatly saves the material cost compared with other processes.

2.High penetration rate can prevent gap corrosion, prolong service life and reduce heat transfer resistance.

3.No material restriction, different materials can be used for processing.

4.Easy for secondary processing, can be directly coiled and bent.

5.The welding heat affected zone and the metallographic change are small, which makes it possible to process the small diameter finned tube.

6.A variety of material combinations are available, titanium/ copper, titanium/titanium, carbon steel/carbon steel, stainless steel/stainless steel, stainless steel/copper, etc.

Laser Welded Finned Tube(Stainless Steel Welded Pipes) Properties:

1.Advanced technology: the product using laser welding technology, 100% penetration rate.

2.Stable quality: the equipment using full automatic production process, product quality is stable and reliable.

3.High heat efficiency: the product has smaller fin spacing and thin tubes to increase the heat transfer area and heat transfer rate.

4.It can be bent into different shapes to meet different production needs.

Laser Welded Finned Tube(Stainless Steel Welded Pipe) Applications:

1.Power Plants

Cooling towers or cooling water recooling plants with dry, dry / wet or wet operation

Sodium coolers for Fast Breeder power plants

Flue gas cooling and heating in fl ue gas desulfurisation scrubbers (FGD) and nitrogen removing plants

2.Chemical and Pharmaceutical Industry Food & Beverage

Heat exchangers of all kinds for cooling and heating of liquids and gases

Heat exchangers for nitric acid (HNO3) plants, e.g. for the fertilizer industry

Heat exchangers for milk powder production

3.Heat Recovery Plants

Flue gas coolers

Economizers

Waste Heat Recovery Units (WHRU)Heating Industry

Primary heat exchangers in gas heating boilers

Secondary heat exchangers for domestic water heating in condensing boilers

4.General Engineering

Heat exchangers for gas cooling of industrial furnaces

Heat exchangers for tank heating

Oil coolers for vacuum plants, ship plants, pumps etc.

Heat exchangers for oil preheating

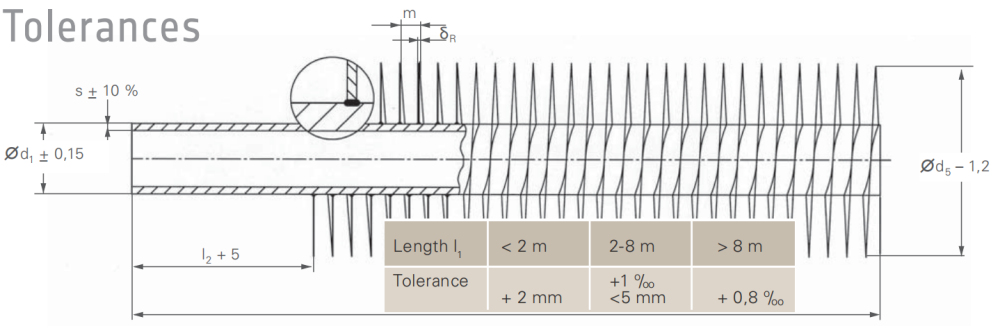

Laser Welded Finned Tube(Spiral Welding Pipe) Specifications:

Product Specification Tube OD 10~215 (mm) 0.4”~8.5” Tube Wall Thk 1~6 (mm) 0.04”~0.24” Tube Length ≤18,500 (mm) ≤60.7ft Fin Thk 0.3~2.0 (mm) 0.01”~0.08” Fin Height 3~30 (mm) 0.12”~1.2” Fin Pitch 2~20 (mm) 1~13 FPI Fin Type Solid, Serrated Material Combinations Fin Material S.S. C.S. Aluminum Copper Titanium Tube Material S.S. C.S. Copper Titanium Applied

Temperature 450°C Type of Service High temperature

Product Categories : Laser Welded Finned Tube

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.